How to Maintain and Troubleshoot a Discharge Valve Pump for Optimal Performance

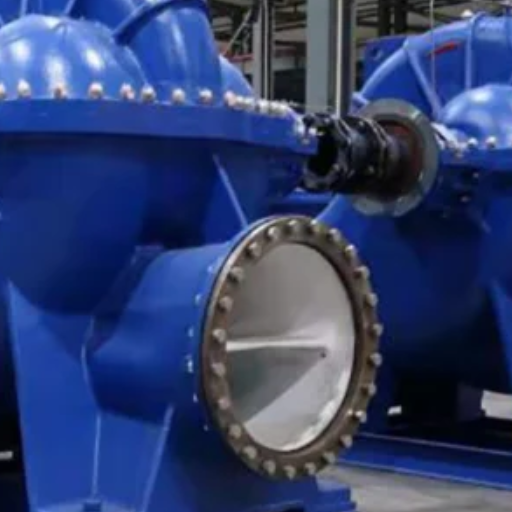

In industrial fluid dynamics, the reliability of a pumping system is often determined not just by the pump itself, but by the ancillary components that control flow and pressure. Among these, the discharge valve is a critical element. It serves as the primary control point for regulating the flow rate and system head in centrifugal pump applications. While the pump generates the kinetic energy required to move fluids, the discharge valve manages how that energy is applied to the downstream piping system.

Neglecting this component can lead to catastrophic system failures, ranging from cavitation and water hammer to complete mechanical seizure. For facility managers and maintenance engineers, understanding the intricacies of the discharge valve pump assembly is essential for ensuring operational continuity and safety. This guide examines the technical function of discharge valves, outlines rigorous maintenance protocols, and provides a framework for troubleshooting common hydraulic and mechanical issues.

Understanding the Discharge Valve and Its Role in Pump Systems

What is a Discharge Valve?

A discharge valve is a mechanism installed on the outlet side of a pump. Its primary function is to isolate the pump from the system for maintenance and to throttle the flow to achieve the desired operating point. In many industrial setups, this valve acts as the final control element, determining the pressure and volume of fluid that enters the discharge piping.

Unlike suction valves, which must remain fully open during operation to prevent cavitation, discharge valves are frequently manipulated to adjust the system’s duty point. They must be robust enough to withstand high pressure, turbulent flow, and the mechanical stresses associated with starting and stopping high-capacity pumps.

How Discharge Valves Work in Centrifugal Pumps

In centrifugal pump systems, the relationship between the pump and the discharge valve is defined by the pump performance curve. When a centrifugal pump is started, it is standard practice to keep the discharge valve closed (or partially closed) to reduce the starting torque on the motor. This creates a "dead-head" condition where the pump generates maximum pressure but zero flow.

As the discharge valve opens, the resistance in the system decreases, allowing flow to increase while pressure drops according to the pump's specific curve. By throttling this valve, operators can artificially increase friction loss (head) to force the pump to operate back on its curve. This is crucial for preventing the pump from running out to "runout" conditions—a state of high flow and low pressure that can cause motor overload and severe cavitation.

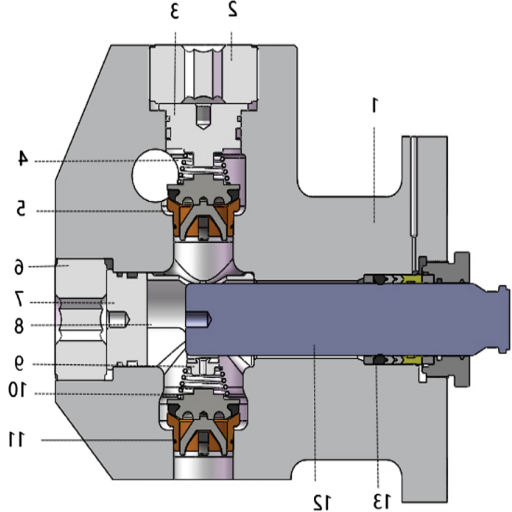

Components of a Discharge Valve Assembly

A comprehensive maintenance plan requires familiarity with the valve’s anatomy. While designs vary (e.g., gate, globe, butterfly, or ball valves), most discharge valves share core components:

The Body: The outer casing that contains the fluid pressure.

The Bonnet: The cover that provides access to the internal parts and houses the stem packing.

The Trim: This includes the moving parts responsible for flow control—the stem, the seat, and the disc (or gate/ball).

The Actuator: The mechanism that operates the valve, which can be a manual handwheel, a gear operator, or an automated pneumatic/electric motor.

Packing and Seals: Materials used to prevent fluid from leaking along the stem or between body joints.

Maintenance Strategies for Discharge Valve Pumps

Regular Inspection and Cleaning

Routine visual inspections should be conducted while the system is pressurized and operational. Technicians should look for external signs of distress, such as weeping around the gland packing or gasket joints. Corrosion on the valve body or the stem threads suggests chemical incompatibility or environmental degradation.

Cleaning is equally vital. Debris accumulation on the stem threads can increase the torque required to operate the valve, potentially leading to actuator failure. External surfaces should be kept free of grime and process buildup to facilitate easy inspection and heat dissipation. In systems handling slurries or fluids with suspended solids, internal flushing may be necessary during shutdowns to prevent sediment from solidifying in the valve seat.

Checking the Condition of Valve Components

Over time, the high-velocity fluid passing through a throttled discharge valve can cause erosion, particularly on the seating surfaces. This phenomenon, known as "wire drawing," creates small channels in the metal that prevent the valve from sealing tightly.

During scheduled shutdowns, the valve should be cycled (opened and closed) to verify smooth operation. If the valve feels gritty or requires excessive force to turn, it indicates internal damage or stem bending. Non-destructive testing (NDT) methods, such as ultrasonic thickness testing, can be employed on the valve body to check for wall thinning caused by corrosion or erosion, ensuring the pressure boundary remains intact.

Importance of Lubrication and Sealing

Friction is the enemy of mechanical longevity. The valve stem threads and the yoke nut require periodic lubrication with a high-grade grease suitable for the operating temperature and environment. Lack of lubrication can cause galling—a form of wear caused by adhesion between sliding surfaces—which can seize the valve in a fixed position.

The gland packing, which seals the stem, requires adjustment rather than just replacement. It should be tight enough to prevent significant leakage but loose enough to allow the stem to move freely. In modern valves utilizing mechanical seals, operators must monitor the seal flush plans to ensure the seal faces remain cool and clean. If a valve utilizes a gearbox actuator, the oil level and quality must be checked regularly to prevent gear tooth wear.

Troubleshooting Common Issues with Discharge Valves

Identifying Signs of Valve Failure

The symptoms of a failing discharge valve often manifest as system anomalies.

Passing: If the pump is shut down and isolated, but the discharge pressure gauge remains high or fluid continues to flow, the valve is "passing" (leaking internally). This indicates a damaged seat or disc.

Vibration and Noise: Excessive vibration localized at the valve suggests turbulence or cavitation caused by the valve being throttled too aggressively. A chattering sound may indicate that the internal trim is loose or that the valve is sized incorrectly for the flow rate.

Stiff Operation: If an automated valve lags in response to control signals, or a manual valve is difficult to turn, it typically points to stem corrosion, bent stems, or dried-out packing.

External Leakage: Visible fluid dripping from the stem area indicates packing failure, while leakage between the body and bonnet suggests a compromised gasket.

Steps for Closing the Discharge for Repairs

Safety protocols are non-negotiable when preparing a discharge valve for repair. The high pressure stored within the discharge piping presents a significant kinetic energy hazard.

System Shutdown: Stop the pump motor and allow the rotation to cease completely.

Lock-Out Tag-Out (LOTO): Isolate the power source to the pump motor to prevent accidental startup.

Isolation: Close the suction valve and any downstream isolation valves to segregate the discharge valve.

Depressurization: Slowly open drain or vent valves to release trapped pressure. Never attempt to loosen valve bolts on a pressurized system.

Drainage: Ensure the liquid is drained into an appropriate containment system, especially if the fluid is hazardous.

Resolving Suction or Discharge Problems

Problems at the discharge valve can often mimic or cause issues elsewhere in the pump. For instance, if a discharge valve is stuck in a throttled position, the pump may run to the left of its Best Efficiency Point (BEP), causing high radial loads and shaft deflection.

If the valve fails to open, the pump will dead-head. To resolve this, verify the actuator is functioning. If the actuator is working but the valve won't move, the internal disc may be wedged into the seat due to thermal expansion. In this case, the system must be depressurized and cooled before attempting to free the valve. Conversely, if the valve fails to close, it creates a backflow risk when the pump stops. This requires immediate inspection of the check valve (often located near the discharge valve) and the discharge valve seat for debris preventing closure.

Optimizing Pump Performance Through Proper Operation

Best Practices for Operating the Discharge Valve

The discharge valve should be used as a precision instrument. During startup, the valve should generally be in a closed or nearly closed position (for centrifugal pumps) to minimize the prime mover's starting load. Once the pump reaches operating speed, the valve should be opened slowly. This gradual introduction of flow prevents hydraulic shock (water hammer) to downstream equipment.

For flow control, operators should avoid throttling the valve below the pump’s minimum continuous stable flow (MCSF). Operating below this limit induces internal recirculation within the pump volute, leading to vibration and impeller damage. If low flow is consistently required, a recirculation line or a Variable Frequency Drive (VFD) is a superior solution to aggressive valve throttling.

Understanding Risks Associated with Improper Use

Mismanagement of the discharge valve creates severe mechanical risks.

Water Hammer: Rapidly closing a discharge valve stops the fluid column instantly, causing a pressure wave to travel back through the pipe. This shockwave can rupture pipes, crack valve bodies, and damage pump casings.

Heat Buildup: Running a pump against a fully closed discharge valve for an extended period converts the pump's mechanical energy into heat. This can boil the fluid inside the casing, destroying seals and potentially causing an explosion.

Cavitation: Throttling a valve can sometimes create a high-velocity jet that causes localized pressure drops below the fluid's vapor pressure, leading to cavitation damage on the valve trim and downstream piping.

When to Seek Professional Help for Pump Issues

While routine maintenance can be handled in-house, certain scenarios necessitate external expertise. If vibration analysis reveals harmonic resonance between the pump and valve, or if non-destructive testing indicates structural weaknesses in the valve body, specialized engineering support is required. Furthermore, retrofitting a manual discharge valve with an automated actuator involves complex torque calculations and control integration that should be managed by the manufacturer or a certified specialist.

Frequently Asked Questions (FAQ)

Can I use a butterfly valve as a discharge valve?

Yes, butterfly valves are commonly used as discharge valves, particularly in large-diameter pipes where space and weight are concerns. However, they are generally better suited for isolation or limited throttling. For precise flow control, globe valves are often preferred, although they create a higher pressure drop.

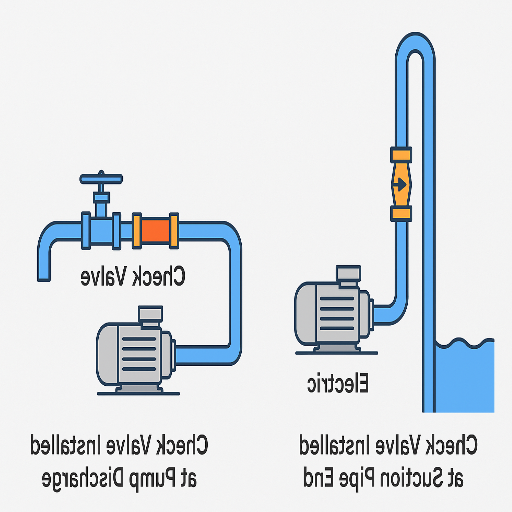

What is the difference between a discharge valve and a check valve?

A discharge valve is a control or isolation device that is manually or automatically operated to regulate flow. A check valve is an automatic safety device that allows fluid to flow in only one direction, preventing backflow into the pump when it stops. Both are typically located on the discharge side of the pump.

Why does my discharge valve make a screaming noise?

High-pitched noise usually indicates cavitation or high fluid velocity across the valve seat. This occurs when the valve is throttled too much, causing a massive pressure drop. It can also happen if the valve is undersized for the system's flow rate.

How often should discharge valves be replaced?

There is no fixed timeline for replacement; it depends on the service conditions. In benign water applications, a high-quality valve can last 20 years. In abrasive slurry or corrosive chemical applications, the service life may be significantly shorter. Condition monitoring and regular inspections should dictate replacement schedules.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More