How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the compressor is often described as the heart of the HVAC system, the valves within it function as the critical arteries that direct flow and maintain pressure. Among these, the discharge valve plays a pivotal role in the thermodynamic cycle of refrigeration.

For HVAC technicians, facility managers, and engineering professionals, understanding the mechanics of the discharge valve is essential for troubleshooting and ensuring system longevity. This component is the gateway between low-pressure gas and high-pressure liquid potential. When it functions correctly, the system operates at peak efficiency. When it fails, it can lead to catastrophic compressor damage and skyrocketing energy costs. This article examines the technical function of the discharge valve, its impact on system performance, and the maintenance protocols necessary to preserve the integrity of cooling infrastructure.

Understanding the Role of the Discharge Valve in HVAC and Refrigeration

What is a Discharge Valve?

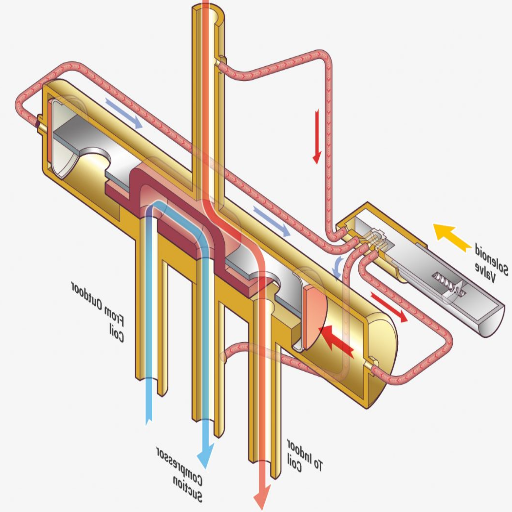

In reciprocating compressors, the discharge valve is typically a reed or flapper valve located on the valve plate at the top of the cylinder. It is a non-return check valve designed to allow flow in only one direction.

During the intake stroke, the piston moves down, creating a vacuum that opens the suction valve and draws in low-pressure refrigerant vapor. During the compression stroke, the piston moves up, compressing the gas. When the pressure inside the cylinder exceeds the pressure in the discharge line (the "high side" of the system), the discharge valve acts against its spring tension (or inherent material tension) to open. This releases the high-temperature, high-pressure superheated vapor into the discharge line, traveling toward the condenser coil.

Once the piston begins its downward stroke again, the pressure differential reverses immediately. The discharge valve must snap shut instantly to prevent the high-pressure gas from flowing back into the cylinder. If this seal is not perfect, the system loses volumetric efficiency.

How Discharge Valves Impact Compressor Functionality

The compressor's primary function is to establish a pressure differential. The discharge valve preserves this differential. If the valve fails to seat properly—a condition often referred to as "blow-by"—hot gas from the discharge line leaks back into the cylinder during the suction stroke.

This re-expansion of gas has several detrimental effects on compressor functionality:

Reduced Capacity: The space in the cylinder that should be filled with new, cool suction gas is instead occupied by expanded hot gas. This reduces the mass flow rate of the refrigerant, meaning the system moves less heat per cycle.

Elevated Temperatures: Re-compressing already hot gas causes discharge temperatures to spike. Excessive heat is the primary enemy of compressor oil and motor windings.

Oil Breakdown: High discharge temperatures can cause the lubricating oil to carbonize or break down, leading to sludge formation which further impedes valve movement.

The Crucial Role of Pressure Relief Valves

It is important to distinguish the working discharge valve from the pressure relief mechanisms often associated with the discharge line. Many systems incorporate an Internal Pressure Relief (IPR) valve or an external discharge relief valve.

These are safety devices designed to open if the differential pressure between the high and low sides exceeds a safe limit (typically around 400 to 500 psi difference). While the standard discharge valve cycles hundreds of times per minute to facilitate operation, the relief valve operates only during system faults—such as a blocked condenser fan or a dirty coil—to prevent the compressor shell from exploding or the mechanical linkages from snapping under load. Understanding the difference between a cycling discharge valve and a safety relief valve is vital for diagnostic accuracy.

Effects of Discharge Valve on Air Conditioning Performance

Impact on Temperature Control

The immediate result of a leaking or damaged discharge valve is a loss of cooling capacity. Because the compressor is not pumping the designed volume of refrigerant to the condenser, there is less liquid refrigerant available to feed the expansion device. Consequently, the evaporator coil is starved of refrigerant.

For the end-user, this manifests as an air conditioning system that runs continuously but fails to reach the setpoint temperature. In commercial refrigeration, this inability to pull down temperature can lead to product spoilage. The discharge air from the supply vents may feel lukewarm rather than cold, indicating that the heat exchange process is compromised.

Influence on System Efficiency

Efficiency in HVAC is often measured by the Energy Efficiency Ratio (EER) or Seasonal Energy Efficiency Ratio (SEER). These metrics essentially calculate how much cooling output is achieved for every watt of electricity consumed. A faulty discharge valve destroys these ratios.

When high-pressure gas leaks back into the cylinder, the compressor motor must work harder to re-compress that gas. It is expending electrical energy to move the same refrigerant molecules multiple times without completing a refrigeration cycle. This results in high amperage draw on the compressor motor.

Furthermore, because the cooling capacity is reduced, the system must run for longer periods to satisfy the thermostat. The combination of longer run times and higher electrical draw creates a compounding effect that significantly increases operational costs. In large-scale chillers or commercial AC units, a single faulty discharge valve can result in thousands of dollars in wasted energy annually.

Common Issues Related to Discharge Valve Malfunctions

Several specific failure modes are associated with discharge valves:

Coking and Sludge: Overheated oil forms carbon deposits on the valve plate. These deposits prevent the reed valve from seating flush against the port, creating a permanent leak path.

Acid Etching: If moisture enters the system, it reacts with the refrigerant and oil to form acid. This acid eats away at the precision-machined surfaces of the valve and valve plate (pitting), destroying the seal.

Metal Fatigue: Discharge valves open and close millions of times. Eventually, the metal can fatigue and snap. A broken piece of valve reed can fall into the cylinder, causing severe damage to the piston and cylinder walls.

Liquid Slugging: If liquid refrigerant enters the cylinder (due to low load or overcharge), liquids cannot be compressed. The extreme hydraulic pressure forces the discharge valve open violently, often bending or breaking it.

Maintenance and Service for Discharge Valves

Routine Checks and Balancing Pressure

Technicians should perform specific diagnostics to assess valve health during routine maintenance.

Compression Efficiency Test: By measuring the suction and discharge pressures, a technician can evaluate the compression ratio. If the suction pressure is abnormally high and the discharge pressure is abnormally low, it suggests the compressor is inefficient, likely due to valve leakage.

Discharge Line Temperature (DLT): Measuring the temperature of the discharge line roughly six inches from the compressor is a standard diagnostic. If the DLT is significantly higher than the saturation temperature of the condensing pressure plus the expected superheat, it indicates re-compression of gas caused by a leaking valve.

Pump Down Test: For systems with pump-down capability, a technician can close the liquid line service valve and let the compressor pull the suction side into a vacuum. Once the compressor turns off, if the suction pressure rises rapidly, it indicates that high-pressure gas is leaking back through the discharge valve.

Replacing Service Valves and Their Importance

In addition to the internal valves, the external Discharge Service Valve (often a rotolock valve or a stem valve) requires maintenance. This valve allows technicians to isolate the compressor from the rest of the high side for service.

Over time, the packing glands on these service valves can dry out and leak refrigerant. During service, it is critical to ensure the valve stem is back-seated (turned fully out) to seal the service port when not in use. If a service valve is leaking, it can often be repaired by tightening the packing nut or replacing the valve core. However, if the main body is damaged, the refrigerant must be recovered, and the valve must be unbrazed and replaced. This procedure requires nitrogen purging to prevent oxidation inside the lines, ensuring no debris damages the internal discharge valves later.

Signs That Your Discharge Valve Needs Attention

Operators and technicians should look for these key indicators of valve distress:

The "Hammering" Noise: A distinct clattering sound during operation often indicates liquid slugging or a broken valve component bouncing inside the head.

Hot Compressor Shell: If the top of the compressor is too hot to touch (beyond normal operating limits), it is a sign of excessive heat of compression due to valve blow-by.

Tripping Breakers: As the motor strains against the inefficiency of a leaking valve, the amperage may exceed the breaker rating or trigger the thermal overload protection.

Advancements in Discharge Valve Technologies

Scroll Compressors and Modern Discharge Valves

While reciprocating compressors use reed valves, scroll compressors dominate the residential and light commercial market today. Scroll compressors operate on a different principle, using two interleaving scrolls to pump refrigerant.

Scrolls typically utilize a discharge check valve located above the fixed scroll. This valve's primary purpose is to prevent the high-pressure gas in the condenser from driving the scrolls in reverse when the power is cut. Reverse rotation creates noise and can cause mechanical wear. The design of the scroll discharge port is inherently more efficient than reed valves because it eliminates the "re-expansion volume" issue found in piston compressors, contributing to the generally higher SEER ratings of scroll units.

Innovative Pressure Management Solutions

Modern systems are increasingly integrating digital intelligence with mechanical components.

Electronic Expansion Valves (EEVs): While located on the liquid side, EEVs communicate with sensors on the discharge line. By strictly controlling the superheat returning to the compressor, EEVs prevent liquid slugging, which is the leading cause of discharge valve breakage.

Digital Discharge Temperature Protection: Advanced control boards now monitor discharge line temperature in real-time. If the temperature approaches the safety limit (often around 225°F or 107°C), the controller can modulate the system or shut it down to save the valves and oil before permanent damage occurs.

The Future of HVAC Systems with Enhanced Discharge Valves

Future developments in valve technology focus on materials science and aerodynamics. Engineers are experimenting with high-fatigue-strength steel alloys and specialized polymers (like PEEK) for valve reeds that can withstand higher temperatures and corrosive environments.

Additionally, "smart valves" in large-scale industrial compressors are being developed to adjust lift and timing based on load conditions, similar to variable valve timing in automotive engines. This would allow for unprecedented control over compression ratios and part-load efficiency.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

Understanding the Discharge Valve Function in Industrial Pumping Systems and Applications

December 15, 2025In the complex ecosystem of industrial fluid dynamics, the stability and efficiency of a system often hinge on the performance of Read More

Read More