Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are two critical components: the suction valve and the discharge valve. While they may appear similar in construction, their roles within the fluid dynamics of a pump are distinct and essential for maintaining operational stability.

Understanding the specific functions, mechanics, and interactions of these valves is necessary for any engineer or operator looking to optimize system performance. This guide provides an in-depth analysis of suction and discharge valves, exploring how they influence pressure, flow regulation, and overall efficiency in industrial applications.

Introduction to Valves in Pump Systems

Overview of Suction and Discharge Valves

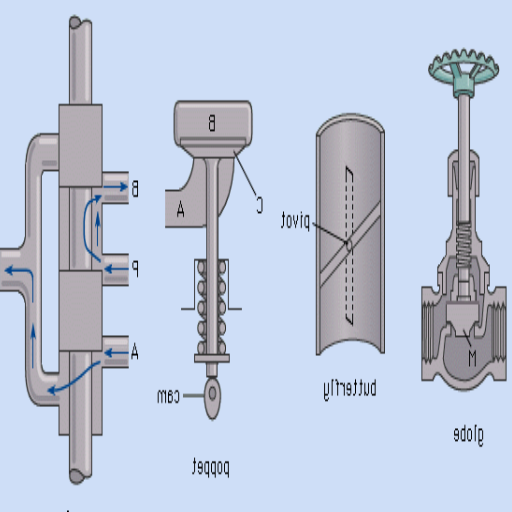

A suction valve controls the entry of fluid into the pump chamber, while a discharge valve manages the exit of pressurized fluid into the system. These are typically check valves—automatic valves that open and close based on differential pressure rather than external actuation.

In a reciprocating pump, for example, the backward stroke of the piston creates a vacuum, causing the suction valve to open and admit fluid. The forward stroke pressurizes the fluid, forcing the suction valve closed and the discharge valve open. This cyclical action is the fundamental operating principle of many positive displacement pumps.

Importance of Valves in Pump Efficiency

The efficiency of a pump is directly tied to the performance of its valves. Leaking, sticking, or delayed valve action can lead to significant energy losses.

Volumetric Efficiency: If a discharge valve fails to seal properly, high-pressure fluid can flow back into the pumping chamber, reducing the net output. Similarly, a leaking suction valve allows fluid to be pushed back into the supply line during the compression stroke.

Energy Consumption: Malfunctioning valves require the prime mover (motor or engine) to work harder to achieve the same flow rate, increasing energy costs.

Mechanical Wear: Poor valve dynamics can cause cavitation, fluid hammer, and excessive vibration, leading to premature wear on bearings, seals, and other system components.

Key Components of Pump Systems

To understand valve function, one must view them within the broader system. The key components interacting with these valves include:

The Pump Chamber/Cylinder: The space where fluid is drawn in and pressurized.

The Piston or Plunger: The moving element that changes the volume of the chamber to create pressure differentials.

The Manifolds: Piping arrangements that direct flow to the suction valve and away from the discharge valve.

Springs and Retainers: Mechanical parts that ensure valves return to their seated positions rapidly after actuation.

Functions of the Suction Valve

Role of the Suction Valve in Fluid Dynamics

The suction valve must facilitate the smooth transition of fluid from a low-pressure source (the suction manifold) into the pump chamber. This process is sensitive to pressure conditions. If the resistance across the suction valve is too high, the pressure in the cylinder may drop below the fluid's vapor pressure.

When this occurs, the fluid vaporizes, creating gas bubbles. As pressure increases during the subsequent stroke, these bubbles collapse violently—a phenomenon known as cavitation. Cavitation can cause severe pitting damage to valve surfaces and cylinder walls. Therefore, the suction valve is designed to offer minimal resistance to flow while maintaining a robust seal.

Mechanics of Suction Valve Operation

Suction valves operate on differential pressure.

Opening Phase: As the pumping element (piston/plunger) retracts, the volume in the chamber increases, causing pressure to drop below that of the suction manifold. This pressure difference overcomes the force of the valve spring, lifting the valve plate or poppet off its seat. Fluid flows into the chamber.

Closing Phase: As the piston reaches the end of its stroke and begins to reverse direction, fluid velocity drops to zero. The spring force, assisted by the rising pressure in the cylinder as compression begins, snaps the valve shut.

This operation must be rapid. A delayed closure results in "slip," where fluid is pushed back into the suction line before the valve seals, reducing efficiency.

Impact on System Pressure and Performance

The suction valve sets the baseline for the pump's cycle.

NPSH (Net Positive Suction Head): The suction valve design influences the Net Positive Suction Head Required (NPSHr). A restrictive valve increases the NPSHr, meaning the system requires higher inlet pressure to prevent cavitation.

Flow Stability: A properly functioning suction valve ensures the cylinder fills completely on every stroke. Incomplete filling leads to flow pulsation and mechanical shock loading on the pump's power end.

Functions of the Discharge Valve

Role of the Discharge Valve in Fluid Dynamics

While the suction valve focuses on admission, the discharge valve focuses on containment and release. It acts as a check against the system's backpressure.

Once the fluid in the chamber is compressed to a level exceeding the pressure in the discharge line, the discharge valve opens. This release must be controlled to prevent pressure spikes. The valve also serves as a critical safety barrier; if the pump stops, the discharge valve prevents the high-pressure column of fluid in the discharge line from flowing backward through the pump, which could cause reverse rotation or mechanical damage.

Mechanics of Discharge Valve Operation

Like the suction valve, the discharge valve relies on differential pressure, but the forces involved are typically much higher.

Opening Phase: As the piston moves forward, compressing the fluid, pressure within the cylinder rises rapidly. Once cylinder pressure exceeds the pressure in the discharge manifold (plus the spring force holding the valve closed), the valve lifts.

Flow Phase: Fluid is expelled from the cylinder at high velocity. The valve must remain stable in the open position to prevent "chatter," which can damage the sealing surfaces.

Closing Phase: As the piston reaches the end of the compression stroke, flow decelerates. The spring pushes the valve toward the seat. Crucially, the valve must seat fully before the piston begins its retraction (suction) stroke. If it remains open as the piston retracts, high-pressure fluid will rush back into the cylinder, causing a massive loss of efficiency and potentially damaging shock waves.

Impact on System Pressure and Performance

The discharge valve directly influences the maximum pressure capability and smoothness of the flow.

Pressure Containment: The valve must provide a leak-free seal against the maximum system pressure. Even minor leaks can erode the valve seat quickly due to the high-velocity "wire drawing" effect of pressurized fluid escaping through a small gap.

Pulsation Control: Reciprocating pumps inherently produce pulsating flow. The timing of the discharge valve opening and closing affects the amplitude of these pulsations. Proper valve dynamics help minimize hydraulic noise and vibration in the downstream piping.

Comparative Analysis: Suction vs. Discharge Valves

Key Differences in Design and Functionality

While the fundamental mechanical design (plate, spring, seat, cage) is often similar, the operational context differs:

Pressure exposure: Discharge valves are subjected to the full discharge pressure of the system continuously when closed. Suction valves are subjected to this pressure intermittently (during the compression stroke) but must seal against it perfectly to prevent backflow.

Spring sizing: Springs in suction valves are often lighter. A heavy spring on a suction valve would increase the pressure drop required to open it, potentially leading to cavitation. Discharge valves may utilize stiffer springs to ensure positive closing against the high-velocity flow at the end of the stroke.

Flow characteristics: Suction valves handle fluid that is often at lower velocity and lower pressure but is highly sensitive to pressure drops. Discharge valves handle high-velocity, high-pressure fluid where minimizing resistance is less critical than ensuring robust sealing and durability.

How Each Valve Contributes to Overall Efficiency

The total efficiency of the pump is the product of the efficiencies of both valves.

Suction Valve Contribution: Primarily dictates volumetric efficiency by ensuring the cylinder fills completely. It prevents the formation of voids (cavitation) that reduce the effective volume of the stroke.

Discharge Valve Contribution: Primarily dictates volumetric efficiency by preventing product loss. It ensures that the work done to compress the fluid results in downstream flow rather than internal recirculation.

If a suction valve fails, the pump creates noise and fails to build pressure. If a discharge valve fails, the pump may still build pressure, but the flow rate will fluctuate wildly, and the power consumption will spike as the motor re-compresses the same fluid repeatedly.

Common Applications in Industrial Settings

These valve configurations are ubiquitous in positive displacement pump applications across various sectors:

Oil and Gas: In mud pumps for drilling operations and plunger pumps for hydraulic fracturing, valves must handle abrasive slurries and extreme pressures. Here, valve inserts are often made of urethane or other durable polymers to resist abrasion.

Chemical Processing: Metering pumps rely on extremely precise suction and discharge valves (often ball check valves) to ensure exact dosages of chemicals are injected into a process stream.

Water Jetting: High-pressure water jetting for cleaning or cutting requires valves that operate at pressures exceeding 20,000 PSI. In these applications, valve response time is critical to maintaining a steady cutting stream.

Power Generation: Boiler feed pumps utilize heavy-duty valves to supply water to steam boilers against high backpressure. Reliability here is paramount, as pump failure can trip a power plant turbine.

Recently Posted

-

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More -

Understanding the Discharge Valve Function in Industrial Pumping Systems and Applications

December 15, 2025In the complex ecosystem of industrial fluid dynamics, the stability and efficiency of a system often hinge on the performance of Read More

Read More