How Discharge Valve Assembly Impacts Fluid Flow Efficiency in Systems

In industrial fluid handling, the efficiency of a system is rarely defined by the power of the pump alone. While the pump provides the necessary energy to move fluid, the control and direction of that energy are dictated by smaller, often overlooked components. Among these, the discharge valve assembly stands as a primary determinant of hydraulic efficiency, metering accuracy, and overall system longevity.

A hydraulic system is a complex network where pressure, velocity, and flow rate must be meticulously balanced. The discharge valve assembly acts as the gatekeeper on the high-pressure side of the pump. Its performance directly correlates to the volumetric efficiency of the operation. If a discharge valve fails to seat correctly, delays in opening, or restricts flow unnecessarily, the energy consumption of the system rises while throughput degrades.

For engineers, plant managers, and maintenance technicians, understanding the intricacies of these assemblies is not merely about parts replacement. It is about understanding fluid dynamics at a granular level. A comprehensive grasp of how discharge valve assemblies function, the variations available in the market, and the specifications required for specific applications is essential for maintaining optimal operational standards in chemical processing, water treatment, and petrochemical industries.

Understanding Discharge Valve Assembly

What is a Discharge Valve Assembly?

Technically, a discharge valve assembly is a unidirectional flow control device located at the outlet of a pump's liquid end. In the context of positive displacement pumps—such as reciprocating metering pumps—it functions as a check valve.

During the suction stroke of the pump, the discharge valve remains closed, preventing the backflow of pressurized fluid from the discharge line into the pump chamber. During the discharge stroke, the pressure generated by the piston or diaphragm overcomes the line pressure and the valve's internal spring force (if equipped), causing the valve to open and allowing fluid to exit. The "assembly" refers to the collective unit, which typically includes the valve body, internal moving parts, seals, and connections.

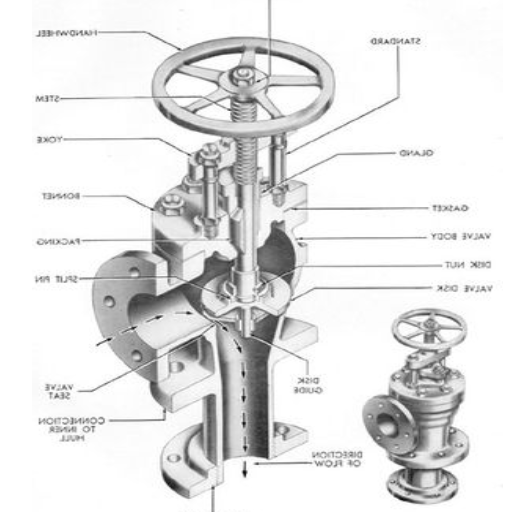

Components of a Discharge Valve Assembly

The reliability of the assembly depends on the interaction of its constituent parts. While designs vary based on the manufacturer and application, the core components generally include:

The Valve Body: The external housing that contains the internal components and connects to the piping system. It must be constructed from materials chemically compatible with the process fluid.

The Seat: A precision-machined ring against which the sealing element rests. The integrity of the seat surface is critical; even microscopic abrasions can lead to internal leakage or "slip."

The Sealing Element (Ball or Poppet): This is the dynamic part of the valve that moves off the seat to allow flow and returns to the seat to check flow. Balls are common in metering pumps due to their ability to rotate and wear evenly.

The Guide: This component restricts the lateral movement of the ball or poppet, ensuring it travels in a straight line relative to the seat. Proper guiding prevents vibration and premature wear.

The Spring: Many assemblies utilize a spring to assist the valve in closing quickly before backflow can occur. This is particularly important in high-speed pump applications.

Seals/O-Rings: Elastomeric components that ensure a leak-free seal between the valve body and the pump head or piping connections.

Importance of Valve in Fluid Dynamics

The discharge valve is the primary defense against hydraulic inefficiency. Its role extends beyond simple directional control.

First, it maintains the pressure boundary. Without a properly functioning discharge valve, the pump cannot build the pressure required to inject fluid into a pressurized process stream. Second, it dictates volumetric accuracy. In metering applications where chemical dosing must be precise (often to within ±1%), a valve that allows even a small amount of backflow introduces errors that can disrupt chemical reactions or compromise product quality. Finally, the valve profile influences the Reynolds number of the fluid passing through it; a poorly designed valve can induce turbulence, leading to cavitation and noise, which can erode components downstream.

Types of Discharge Valves

Pulsafeeder Discharge Valve Overview

In the realm of chemical metering, Pulsafeeder style valves are a distinct and widely recognized standard. These assemblies are engineered specifically for diaphragm pumps used in critical dosing applications. They typically feature a guided ball check design that prioritizes repetitive accuracy and ease of maintenance.

The design philosophy behind these assemblies focuses on modularity. They are often cartridge-based, allowing for rapid removal and inspection without dismantling the entire piping infrastructure. This design minimizes downtime—a critical metric in continuous processing environments. The internal geometry of these valves is optimized to reduce pressure drop, ensuring that the maximum amount of pump energy is converted into fluid motion rather than heat or turbulence.

Comparing Different Valve Types

While the guided ball check is common, it is not universal. Understanding the differences between valve architectures is vital for proper selection.

Ball Valves: As noted, these utilize a spherical sealing element. The ball rotates randomly during operation, which distributes wear evenly across its surface. This makes ball valves exceptionally durable and suitable for a wide range of fluids, including those with light particulate matter.

Poppet Valves: These use a flat or conical disc (poppet) on a stem. Poppet valves generally offer a larger flow area for a given diameter compared to ball valves, potentially reducing pressure drop. However, they are more sensitive to particulates, which can become trapped between the poppet and seat, causing leaks. They are ideal for clean, high-pressure fluids.

Flapper (Swing) Valves: These employ a hinged disc that swings open. While they offer very low resistance to flow, they lack the rapid response time and tight sealing capabilities of ball or poppet valves in high-cycle metering applications. They are better suited for general transfer pumps rather than precision dosing.

Application Scenarios for Various Discharge Valves

The application dictates the valve. Misapplication is the leading cause of premature valve failure.

Viscous Fluids: When pumping thick fluids like polymers or syrups, a spring-loaded valve may create too much resistance. In these scenarios, a larger ball valve without a spring (relying on gravity and back pressure to seat) allows the viscous fluid to pass with less restriction.

Slurries and Abrasives: Fluids containing suspended solids require valves with hard seats and balls (such as ceramic or tungsten carbide) to resist erosion. Furthermore, the valve design must have ample clearance to prevent particles from lodging in the guide.

Gassing Fluids: For fluids like sodium hypochlorite that tend to off-gas, standard valves can become "vapor locked." Specialized discharge valves with air-bleed capabilities or specific internal geometries are required to allow gas to pass without interrupting liquid flow.

Specifications and Features

Key Specifications for Efficient Discharge Valve Assembly

When evaluating specifications, three primary factors drive efficiency:

Flow Coefficient (Cv): This value represents the volume of water at 60°F that will flow through the valve per minute with a pressure drop of 1 psi. A higher Cv indicates less flow restriction. Engineers must balance a high Cv with the need for rapid closure; a valve that opens too wide may take too long to close, reducing accuracy.

Cracking Pressure: This is the minimum upstream pressure required to open the valve. In systems with low discharge pressures, the cracking pressure must be low enough to allow flow but high enough to ensure a crisp, positive seal when the pump strokes.

Pressure and Temperature Ratings: The assembly must be rated for the system’s maximum excursion limits, not just the operating average. Thermal expansion of components must be considered, as mismatched expansion coefficients between the valve body and the seat can lead to leakage at high temperatures.

Choosing the Right Valve for Your Pump System

Compatibility is the cornerstone of selection. This involves both chemical and hydraulic compatibility.

Chemical compatibility requires a thorough review of material data sheets. For highly aggressive acids, standard stainless steel may degrade rapidly, necessitating the use of exotic alloys like Hastelloy or polymers like PVDF or PTFE. It is imperative to verify that every wetted component—including the O-rings and springs—is compatible with the process fluid.

Hydraulic compatibility involves sizing. An oversized discharge valve may chatter (rapidly open and close), leading to accelerated wear and water hammer. Conversely, an undersized valve will create excessive back pressure, forcing the pump to work harder and potentially tripping motor overload circuits.

Innovative Features in Modern Discharge Valves

The sector is seeing innovation aimed at reducing maintenance intervals and improving fluid dynamics.

Hydrodynamic Guides: Newer valve guides are being designed using Computational Fluid Dynamics (CFD) to smooth the flow path around the ball. This reduces turbulence and cavitation risk, which preserves the integrity of the fluid and the valve components.

Self-Cleaning Seats: Some modern designs incorporate seat geometries that promote a scouring action by the fluid as it passes. This helps wash away particulates that might otherwise adhere to the sealing surface, maintaining a tight seal in dirty fluid applications.

Tool-Free Maintenance: Innovations in assembly housing allow for "twist-lock" or clamp-style access, enabling technicians to inspect or replace valve cartridges without the need for wrenches, significantly reducing maintenance turnaround time.

Shopping for Discharge Valve Assemblies

Where to Shop for Quality Discharge Valves

Sourcing options generally fall into two categories: Original Equipment Manufacturers (OEM) and specialized aftermarket suppliers.

Purchasing directly from the pump OEM guarantees that the valve meets the exact specifications of the original design. This is often the safest route for critical compliance applications. However, specialized aftermarket manufacturers often provide high-quality alternatives that may offer improved features, such as upgraded materials or modernized designs, often at a more competitive price point. When utilizing third-party suppliers, it is crucial to verify that they specialize in fluid handling components and offer robust technical support.

Evaluating Product Quality and Performance

Quality assurance in valve manufacturing is non-negotiable. When evaluating a supplier, look for the following indicators of quality:

Material Certification: Reputable suppliers should be able to provide Material Test Reports (MTRs) confirming the chemical composition of the metal alloys used in the valve bodies and internal components.

Testing Protocols: Ask about the testing procedures. High-quality discharge valves are often hydrostatically tested at the factory to ensure they hold pressure and do not leak prior to shipment.

Surface Finish: The surface finish of the valve seat and ball is critical. Look for manufacturers who specify Ra (Roughness Average) values, as a smoother finish correlates to a tighter seal and longer lifespan.

Cost Considerations When Purchasing Discharge Valves

Price should always be viewed through the lens of Total Cost of Ownership (TCO). A budget valve assembly constructed from lower-grade materials may save money upfront, but if it requires replacement every three months, the labor costs and process downtime will rapidly dwarf the initial savings.

Investing in a premium valve assembly with wear-resistant materials (like ceramic balls or high-grade alloys) often yields a lower TCO by extending Maintenance intervals (MTBF - Mean Time Between Failures). Furthermore, consider the cost of accuracy. In chemical dosing, a cheap valve that allows slip results in chemical waste. If the chemical is expensive, an inefficient valve can cost thousands of dollars in wasted product annually.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More