Exploring the Design and Functionality of a 1 Ball Valve in Modern Engineering

In the complex world of fluid dynamics and piping systems, the humble valve plays a critical role. It is the gatekeeper, the regulator, and the safety mechanism that ensures systems operate efficiently. Among the vast array of valve types available to engineers and plumbers, the 1-inch ball valve stands out as a versatile standard.

This component is ubiquitous in residential, commercial, and industrial settings. From controlling the water mains in a suburban home to managing chemical flow in a processing plant, the 1-inch ball valve is essential. Understanding its design, specific variations like full port versus standard port, and material benefits is crucial for any professional involved in system design or maintenance.

This guide explores the engineering principles behind the 1-inch ball valve, focusing on heavy-duty brass options and the technical specifications that dictate their performance.

Introduction to Ball Valves

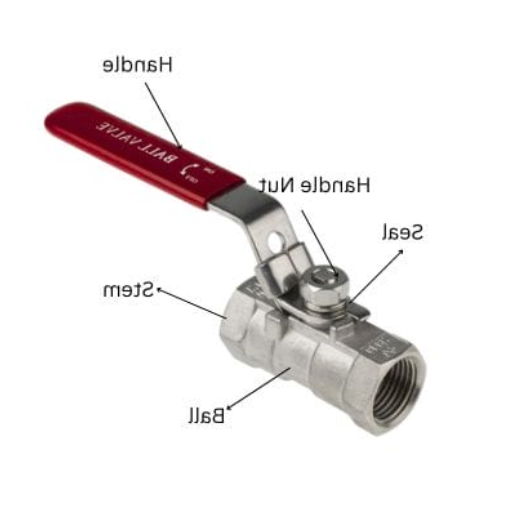

What is a Ball Valve?

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball's hole is in line with the flow and closed when it is pivoted 90 degrees by the valve handle.

Visual Cue: The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status.

Operation: The ease of operation, repair, and versatility lend it to extensive industrial use, supporting pressures up to 1000 bar and temperatures up to 752°F (400°C), depending on design and materials.

Importance of Ball Valve Design in Engineering

Engineering reliability relies on the minimization of failure points. Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff and control applications, where they are often preferred to gates and globe valves.

Key design advantages include:

Low Pressure Drop: Particularly in full port designs, the flow is unobstructed.

Quick actuation: A 90-degree turn opens or closes the valve, allowing for rapid response.

Leak-proof seal: The seating mechanism in modern ball valves provides a tight seal, preventing fugitive emissions or leaks.

Overview of 1 Inch Ball Valves

The 1-inch sizing refers to the nominal pipe size (NPS) of the connections. This size is a "sweet spot" in fluid handling—large enough to facilitate significant flow for residential mains and commercial machinery, but small enough to be cost-effective and compact.

When specifying a 1-inch valve, engineers look at the intersection of volume requirements and space constraints. A 1-inch line can carry a substantial volume of fluid, making the valve's internal geometry critical to maintaining system pressure.

Types of Ball Valves

Full Port vs. Standard Port Ball Valves

The distinction between full port and standard port is a matter of flow dynamics and resistance.

Full Port (Full Bore)

In a full port 1-inch ball valve, the hole in the ball (the bore) has the same diameter as the pipeline.

Flow: Unrestricted. There is no reduction in flow capacity.

Friction: Minimized friction loss.

Application: Ideal for systems where pressure drop must be avoided, or where the line needs to be pigged (cleaned with a mechanical device sent through the pipe).

Standard Port (Reduced Bore)

In a standard port valve, the bore is one pipe size smaller than the valve size. For a 1-inch valve, the internal opening might be closer to 3/4 of an inch.

Flow: Slightly restricted, creating a Venturi effect.

Pressure: Higher pressure drop compared to full port.

Cost: Generally less expensive and more compact.

Application: Used where flow restriction is not critical to system performance.

Brass Ball Valves: Features and Benefits

Material selection is just as important as mechanical design. Brass, an alloy of copper and zinc, remains the gold standard for general-purpose ball valves due to its unique mechanical properties.

Heavy Duty Brass Construction

Heavy-duty brass valves feature thicker walls and robust stems. This added mass translates to higher pressure ratings and greater resistance to mechanical stress from pipes expanding and contracting.

Durability: Brass resists corrosion from water and non-corrosive gases better than carbon steel.

Machinability: Brass can be machined to tight tolerances, ensuring high-quality sealing surfaces.

Thermal Conductivity: While not always a primary factor, brass handles temperature fluctuations well without becoming brittle.

Lead-Free Options for Safety Compliance

In recent years, regulations regarding plumbing materials have shifted significantly to protect public health. The Safe Drinking Water Act (SDWA) in the United States mandates that pipes, plumbing fittings, and fixtures used for potable water must be "lead-free."

Definition: Lead-free is defined as a weighted average lead content of not more than 0.25% for wetted surfaces.

Compliance: For any application involving water intended for human consumption, engineers must specify lead-free brass ball valves.

Identification: These valves are often marked with "LF" or a specific color on the handle (often white or blue) to distinguish them from standard brass valves used for heating or gas.

Technical Specifications of 1 Ball Valves

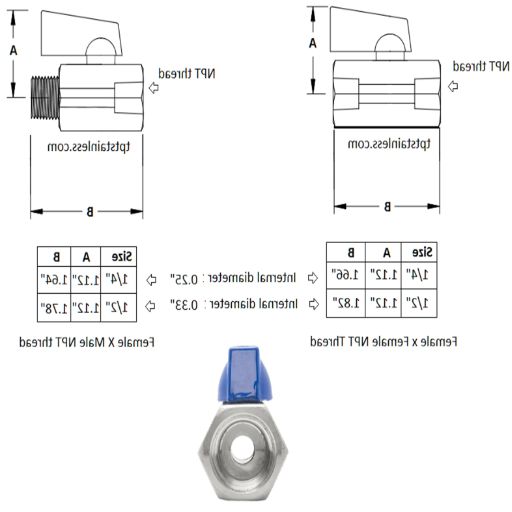

Understanding NPT Threaded Connections

Most 1-inch brass ball valves utilize NPT (National Pipe Taper) threads.

Mechanism: NPT threads are tapered, meaning they get tighter as they are screwed in. This interference fit creates a mechanical seal.

Sealing: While the threads create a seal, PTFE tape or pipe dope is required to fill the microscopic gaps between the mating threads to ensure a leak-free joint.

Compatibility: Ensuring both the pipe and the valve use the same thread standard (NPT vs. BSP) is vital. NPT is the standard in North America.

Pressure Ratings and PSI Considerations

Pressure ratings on valves are typically denoted in two ways: WOG and WSP.

WOG (Water, Oil, Gas): This indicates the maximum pressure the valve can handle at ambient temperatures. A typical heavy-duty 1-inch brass ball valve might be rated 600 WOG, meaning it can withstand 600 PSI of pressure for cold water, oil, or gas.

WSP (Working Steam Pressure): Steam carries more energy and heat, which stresses materials differently. A valve rated 600 WOG might only be rated 150 WSP. This lower rating reflects the material's limitations under high heat.

Why High PSI Matters:

Even if a system operates at 60 PSI (typical residential pressure), a valve rated for 600 PSI offers a significant safety factor. It can withstand water hammer—pressure surges that occur when valves close quickly—without cracking or leaking.

Temperature Range and Its Importance

Temperature affects the sealing materials inside the valve. Most brass ball valves use PTFE (Polytetrafluoroethylene) or RPTFE (Reinforced PTFE) seats.

Standard Range: Typically -4°F to 300°F (-20°C to 149°C).

Extremes: At lower temperatures, seals can become brittle. At higher temperatures, they can deform.

The P-T Curve: Pressure and temperature are related. As temperature rises, the maximum allowable pressure decreases. A valve might handle 600 PSI at 100°F, but only 150 PSI at 300°F.

Applications of 1 Ball Valves

Common Uses in Various Industries

HVAC Systems: used for isolating zones in heating and cooling loops. Full port valves are preferred here to minimize pumping losses.

Residential Plumbing: Main water shutoffs and branch isolation.

Compressed Air Lines: Brass valves are excellent for air systems due to their tight sealing capabilities.

Agricultural Irrigation: Controlling flow to different field sectors.

Industrial Manufacturing: Used in coolant lines, hydraulic setups (low pressure), and general fluid transfer.

Advantages of Using Heavy Duty Brass Ball Valves

Why choose a heavy-duty 1-inch valve over a standard or plastic alternative?

Longevity: Metal fatigue is less of an issue with heavy forged brass.

Stem Integrity: Heavy-duty valves often feature blowout-proof stems, a safety feature where the stem is inserted from the inside, preventing it from being pushed out by high internal pressure.

Torque Resistance: Installing a valve requires tightening it onto a pipe. Heavy-duty bodies resist cracking or deforming during aggressive installation.

Implementation Scenarios

Scenario 1: Commercial High-Rise Retrofit

In a scenario involving the retrofit of a 40-story office building's HVAC system, engineers replaced standard gate valves with 1-inch full port heavy-duty brass ball valves on perimeter heating units.

Challenge: Old gate valves were seizing up and not sealing completely, leading to energy waste and maintenance difficulties.

Solution: The implementation of ball valves allowed for 100% shutoff during maintenance.

Result: The full port design ensured that the new valves did not add static pressure to the system, allowing the existing pumps to operate efficiently without upgrading.

Scenario 2: Municipal Water Treatment Pilot

A water treatment facility utilized 1-inch lead-free brass valves for a pilot sampling skid.

Challenge: The system required components that met strict NSF/ANSI 61 standards for potable water while handling frequent on/off cycling for sampling.

Solution: Lead-free brass ball valves provided the necessary compliance.

Result: The quarter-turn operation allowed technicians to take samples rapidly. The durable PTFE seats withstood thousands of cycles over the pilot period without developing leaks, validating the material choice for the larger plant expansion.

Scenario 3: Pneumatic Workshop Air Supply

A large automotive repair workshop upgraded its compressed air distribution lines.

Challenge: Plastic valves were cracking under the vibration of air compressors and the physical impact of daily shop activity.

Solution: Heavy-duty 1-inch threaded brass valves were installed at all main drops.

Result: The mechanical strength of the brass bodies resisted vibration damage. The blow-out proof stems ensured safety for workers operating near high-pressure air lines (150 PSI).

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More