The Science Behind Ball Valve Shut Off Design and Its Impact on System Performance

Ball valves are fundamental components in fluid control systems, yet their design intricacies and impact on overall system performance are often overlooked. A well-designed shut off valve is crucial for efficiency, safety, and reliability across countless industrial and residential applications. Understanding the science behind these devices—from their internal mechanics to the materials they are made from—is key to optimizing any system they are a part of.

This guide explores the comprehensive world of ball valve shut off design. We will cover the core components and functions of ball valves, compare different types and materials like PVC and stainless steel, and examine how specific design choices, such as port size, affect system dynamics. By the end, you will have the knowledge to select, install, and maintain the right shut off valves to ensure peak performance and longevity for your fluid control systems.

Understanding Ball Valves and Their Functionality

What is a Ball Valve?

A ball valve is a type of quarter-turn shut off valve that uses a hollow, pivoting ball to control the flow of liquid or gas. When the valve is open, the hole in the ball aligns with the flow path, allowing the fluid to pass through. A 90-degree turn of the valve handle or actuator pivots the ball so the hole is perpendicular to the flow path, blocking the flow completely. This straightforward on/off mechanism makes them easy to operate and provides a tight seal when closed, minimizing the risk of leaks.

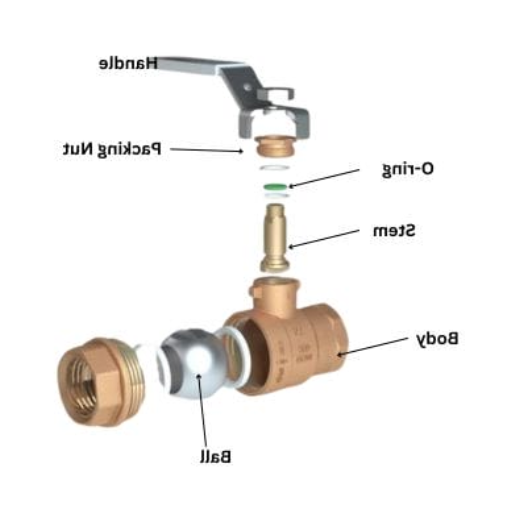

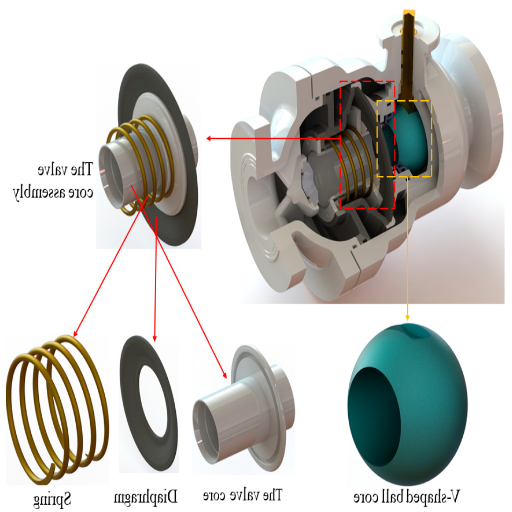

Components of a Ball Valve

The design of a ball valve is relatively simple, consisting of a few key parts that work together to ensure reliable operation.

Valve Body: The main part of the valve that houses all the internal components and connects to the pipeline. It is typically made from durable materials like brass, stainless steel, or PVC.

Ball: A spherical disc with a bore (a hole) through the center. The ball rotates to control the fluid flow. The material of the ball is critical for compatibility with the fluid and operating conditions.

Stem: The shaft that connects the ball to the handle or actuator. When the handle is turned, the stem rotates the ball.

Seats: Two rings, typically made of a soft material like Teflon (PTFE), that sit between the ball and the valve body. The seats create a seal to prevent fluid from leaking around the ball when it is in the closed position.

Handle/Actuator: The external lever or device used to turn the stem and operate the valve. Manual valves have a simple handle, while automated systems may use an electric, pneumatic, or hydraulic actuator.

How Ball Valves Control Flow

The operation of a ball valve is based on a simple rotational motion.

Open Position: When the handle is parallel to the pipe, the bore of the ball is aligned with the flow direction. This creates a straight, unobstructed path for the fluid, resulting in minimal pressure drop and high flow capacity.

Closed Position: A quarter-turn (90 degrees) of the handle moves it perpendicular to the pipe. This rotates the ball, so the solid part of the sphere blocks the flow path. The pressure of the fluid pushes the ball against the downstream seat, creating a tight, reliable seal.

This quick, quarter-turn action is a major advantage, allowing for rapid shut off in emergency situations and providing a clear visual indicator of the valve's status.

Types of Shut Off Valves and Their Applications

Overview of Shut Off Valves

Shut off valves, also known as isolation valves, are designed to stop the flow of fluid in a pipeline. Besides ball valves, other common types include:

Gate Valves: Use a flat gate that slides up and down to open or close the flow path. They are ideal for on/off applications where the valve is not operated frequently.

Globe Valves: Use a movable plug or disc to throttle or regulate flow, making them suitable for applications requiring flow control rather than just on/off operation.

Butterfly Valves: Feature a rotating disc to control flow. They are lightweight, cost-effective, and common in large-diameter pipes.

Plug Valves: Similar to ball valves but use a cylindrical or tapered plug with a bore. They offer quick shut off but can have higher operating torque.

Differences Between PVC and Stainless Steel Ball Valves

The material of a ball valve significantly impacts its performance, durability, and cost. Two of the most common materials are PVC and stainless steel.

PVC (Polyvinyl Chloride) Ball Valves:

Corrosion Resistance: PVC is highly resistant to corrosion from acids, bases, salts, and other chemicals, making it ideal for water treatment, chemical processing, and irrigation systems.

Cost-Effectiveness: PVC valves are generally less expensive than their metal counterparts.

Temperature and Pressure Limits: PVC has lower temperature and pressure ratings than stainless steel. It is not suitable for high-temperature applications or systems with high-pressure surges.

Installation: PVC valves are lightweight and easy to install using solvent cement or threaded connections.

Stainless Steel Ball Valves:

Strength and Durability: Stainless steel offers superior strength and can withstand high pressures and temperatures, making it suitable for demanding industrial applications, including oil and gas, steam, and food processing.

Corrosion Resistance: While PVC excels with many chemicals, stainless steel provides excellent resistance to rust and corrosion in a wide range of environments, especially where sanitation is critical.

Cost: Stainless steel valves are more expensive upfront but offer a longer service life in harsh conditions.

Full Port vs. Standard Port Ball Valves

The size of the bore in the ball determines whether a valve is "full port" or "standard port."

Full Port (Full Bore): The bore diameter is the same as the inner diameter of the pipe. This design creates an unrestricted flow path, resulting in a very low pressure drop. Full port valves are preferred in applications where high flow rates and minimal flow restriction are critical, such as in process lines where pigging (cleaning the pipe internally) is required.

Standard Port (Reduced Bore): The bore diameter is one size smaller than the pipe's inner diameter. This slight restriction creates a minor pressure drop across the valve. Standard port valves are more compact, lighter, and less expensive than full port valves. They are suitable for many general-purpose applications where a small pressure loss is acceptable.

Impact of Ball Valve Design on System Performance

Flow Dynamics in Ball Valves

The primary goal of a shut off valve is to control flow with minimal disruption when open. The internal geometry of the valve plays a crucial role in this.

Pressure Drop: In full port ball valves, the straight and unobstructed flow path results in a very low coefficient of flow (Cv), meaning there is minimal pressure loss as the fluid passes through. This is highly desirable for maintaining system efficiency, as less energy is needed to move the fluid.

Turbulence: A smooth, straight path, as found in a full port ball valve, minimizes turbulence. Reduced turbulence leads to less wear on the valve and downstream components, lower noise levels, and more predictable system behavior. In contrast, valves with more tortuous flow paths, like globe valves, intentionally create turbulence to regulate flow but are less efficient for simple on/off duty.

Advantages of Using PEX and PVC Ball Valves

In modern plumbing and fluid handling, plastic valves made from materials like PEX (Cross-linked Polyethylene) and PVC offer distinct advantages.

Corrosion and Chemical Resistance: Both PEX and PVC are immune to rust and highly resistant to a wide array of chemicals. This makes them ideal for potable water systems, where metal corrosion can contaminate the supply, and for handling corrosive fluids in industrial settings.

Cost and Ease of Installation: Plastic valves are significantly lighter and more affordable than metal alternatives. Their installation methods (e.g., crimping for PEX, solvent cement for PVC) are often faster and require less specialized labor, reducing overall project costs.

Flexibility (PEX): PEX tubing and associated valves are flexible, allowing them to be routed around obstacles easily. This reduces the number of fittings required and minimizes potential leak points.

Best Practices for Selection and Installation

Factors to Consider When Choosing a Shut Off Valve

Fluid Compatibility: The valve materials (body, ball, and seats) must be compatible with the fluid being handled to prevent corrosion, degradation, or contamination.

Temperature and Pressure: Select a valve that can safely operate within the system's expected temperature and pressure ranges. Always check the manufacturer's specifications.

Flow Requirements: Decide between a full port or standard port valve based on whether minimizing pressure drop is a critical requirement for your application.

Application: Is the valve for simple on/off duty, or is flow regulation (throttling) needed? Ball valves excel at on/off control but are not recommended for extended throttling, which can cause premature seat wear.

Operating Environment: Consider external factors like ambient temperature, exposure to corrosive atmospheres, and the need for automation when selecting valve body material and actuator type.

Installation Tips for Optimal Performance

Inspect Before Installing: Before installation, check the valve for any damage that may have occurred during shipping and ensure the interior is clean and free of debris.

Support the Pipeline: Ensure the pipe is properly aligned and supported to prevent mechanical stress on the valve body, which can lead to leaks or operational issues.

Follow Manufacturer's Instructions: Adhere to the manufacturer's specific guidelines for installation, especially for solvent-welded or threaded connections, to ensure a secure, leak-free seal.

Allow for Operation: Install the valve in a location that provides enough clearance to fully operate the handle or to service the actuator.

Maintenance Recommendations for Longevity

Regular Operation: Cycle the valve (fully open and close it) periodically, especially in systems where it remains in one position for long periods. This helps prevent the ball from seizing and clears any minor sediment buildup on the seats.

Inspect for Leaks: Regularly inspect the valve stem packing and body joints for any signs of leakage. Minor packing leaks can often be resolved by tightening the packing nut, but be careful not to overtighten.

Keep Clean: In dirty or corrosive environments, keep the exterior of the valve and the handle mechanism clean to ensure smooth operation and prevent external corrosion.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More