Ball Valve vs Gate Valve: Which One Offers Better Performance and Durability?

When it comes to controlling the flow of liquids or gases in a piping system, choosing the right valve is crucial for efficiency, safety, and longevity. Among the most common options are ball valves and gate valves. Both are widely used across various industries, from residential plumbing to large-scale industrial applications. However, they operate on different principles and are suited for different tasks. Making the wrong choice can lead to operational inefficiencies, frequent maintenance, and even system failure.

This guide will compare ball valves and gate valves to help you make an informed decision. We will explore their design, function, performance characteristics, and ideal applications. By understanding the fundamental differences and specific advantages of each, you can select the valve that best meets the demands of your system, ensuring optimal performance and durability. Whether you are a homeowner tackling a DIY project or an engineer designing a complex industrial process, this comprehensive comparison will provide the clarity you need.

Understanding Valve Types: Ball Valves and Gate Valves

What Is a Ball Valve?

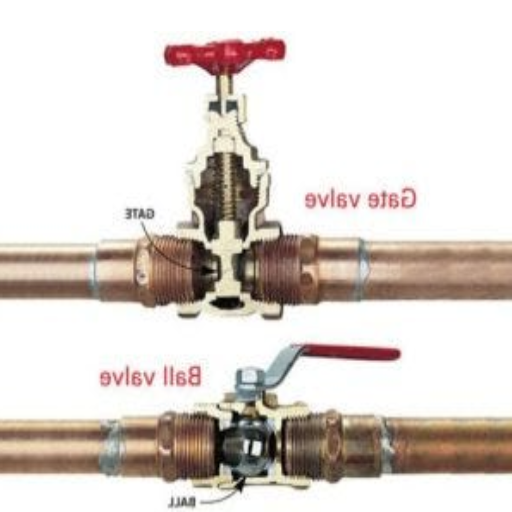

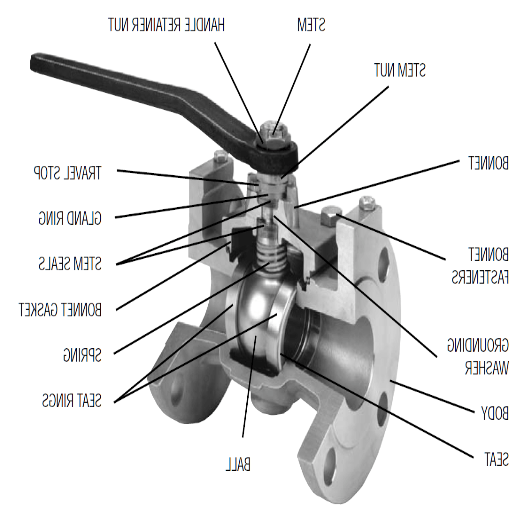

A ball valve is a type of quarter-turn valve, meaning its handle only needs to be turned 90 degrees to go from fully open to fully closed. The "ball" in its name refers to the spherical disc inside the valve body that controls the flow. This ball has a hole, or bore, through its center.

When the valve is open, the bore is aligned with the pipe, allowing fluid or gas to pass through with minimal restriction. When the handle is turned, the ball rotates 90 degrees, and the solid part of the ball blocks the flow path, creating a tight seal. The position of the handle provides a clear visual indicator of the valve's status: parallel to the pipe means it's open, and perpendicular means it's closed. This simple operation makes ball valves quick and easy to use.

What Is a Gate Valve?

A gate valve operates using a multi-turn mechanism. Instead of a quick quarter-turn, its handle must be rotated several times to open or close the valve completely. The control element is a flat or wedge-shaped gate that moves up and down, perpendicular to the flow path.

When the handle is turned, a threaded stem raises the gate, lifting it out of the flow path to open the valve. To close it, the handle is turned in the opposite direction, lowering the gate until it seals firmly against the valve seats. Because the gate moves slowly, these valves are not ideal for applications requiring rapid shut-off. Unlike ball valves, the handle's position does not immediately indicate whether the valve is fully open or closed.

Applications of Ball Valves and Gate Valves

The distinct characteristics of ball and gate valves make them suitable for different jobs.

Ball valves are favored in applications where quick shut-off is necessary. Their ability to create a tight seal also makes them excellent for gas applications and situations where leakage is not an option. You'll commonly find them in:

Residential plumbing (main water shut-offs)

Oil and gas processing

Chemical manufacturing

Food and beverage production

Gate valves are typically used in applications where the valve will be either fully open or fully closed for long periods. They are not designed for throttling or regulating flow, as the partial opening can cause significant wear on the gate and seats. Their straight-through flow path offers very little resistance when fully open, making them ideal for:

Large-scale water supply lines

Wastewater treatment plants

Power generation facilities

High-viscosity fluid applications

Key Differences Between Ball Valves and Gate Valves

Functional Differences: Ball Valve vs Gate Valve

The most apparent functional difference is the speed of operation. A ball valve's quarter-turn design allows for almost instantaneous shut-off. This rapid action is a major advantage in emergency situations or processes that require frequent on/off cycles. The simple handle position also makes it easy to verify the valve's state from a distance.

In contrast, a gate valve's multi-turn operation is slow and deliberate. It takes several full rotations of the handle to move the gate from the open to the closed position. This slow action prevents a phenomenon known as "water hammer," which is a pressure surge caused by a fluid in motion being forced to stop or change direction suddenly. The gradual closing of a gate valve mitigates this risk, making it safer for large-diameter pipelines with high flow rates.

Another key difference is their suitability for throttling. Ball valves can be used for throttling, but it's generally not recommended for extended periods. When a ball valve is partially open, the high-velocity flow can erode the seals and the ball itself, leading to leakage over time. Gate valves are even less suitable for throttling. A partially open gate will vibrate in the flow stream, causing damage to the gate and its seats, which compromises its ability to seal tightly when fully closed.

Performance Comparison: Gate Valve vs Ball Valve

When it comes to sealing performance, ball valves typically have the edge. Their design, which often includes soft seats made from materials like Teflon (PTFE), provides a bubble-tight seal. This makes them the superior choice for applications involving gases or where any amount of leakage is unacceptable. They maintain this tight seal even after many cycles of use.

Gate valves can also provide a strong seal, especially metal-seated gate valves in high-pressure applications. However, their sealing surfaces are more susceptible to wear, especially if used for throttling or if the fluid contains abrasive particles. Over time, the gate and seats can become scored, leading to minor leaks when the valve is closed.

In terms of flow characteristics, gate valves offer less resistance when fully open. The gate retracts completely out of the flow path, creating an unobstructed, straight-through channel. This results in a very low pressure drop across the valve. Ball valves, particularly full-port designs, also offer low flow resistance. However, in reduced-port designs, the bore through the ball is smaller than the pipe's diameter, which creates some restriction and a slightly higher pressure drop.

Durability and Longevity of Each Valve Type

The durability of a valve depends heavily on the application, materials, and maintenance.

Ball valves are generally very durable and reliable, especially in clean fluid applications. Their simple design with fewer moving parts means there is less that can go wrong. The rotating motion of the ball against the seats also has a self-cleaning effect, wiping away any small particles that might accumulate. However, in applications with abrasive or slurry-like fluids, the soft seats can wear out more quickly, requiring replacement.

Gate valves are robust and can have a very long service life, particularly in applications where they are not cycled frequently. Their construction is well-suited for high-temperature and high-pressure environments. The main point of wear is the gate and seat surfaces. If the fluid is abrasive or if the valve is used for throttling, these components can degrade, affecting the valve's ability to seal. The threaded stem can also be a point of failure if it is not properly lubricated or protected from the elements.

When to Use a Gate Valve or Ball Valve

Best Practices for Valve Selection

Before deciding, ask yourself the following questions:

Is quick shut-off required? If you need to stop the flow immediately, a ball valve is the clear winner.

Will the valve be used to regulate flow? Neither is ideal, but some specialized ball valves (V-port ball valves) are designed for throttling. Standard gate valves should never be used for this purpose.

What is the fluid type? For gases or applications requiring a perfect seal, choose a ball valve. For thick, viscous liquids or slurries, a gate valve's unobstructed path is often better.

How often will the valve be operated? For frequent on/off cycles, a ball valve's durability and ease of use are superior. If the valve will remain open or closed for long periods, a gate valve is a reliable option.

Is water hammer a concern? In large pipelines, the slow closing of a gate valve can prevent damaging pressure surges.

Common Scenarios for Using Gate Valves

Gate valves excel in situations where a straight-line flow of fluid and minimal restriction are critical.

Main Water Lines: Their low flow resistance is perfect for city water mains and large industrial water systems.

High-Viscosity Fluids: The unobstructed opening allows thick liquids like heavy oils and grease to pass through easily.

Infrequent Operation: They are ideal as isolation valves in systems that are rarely shut down, such as in power plants or large manufacturing facilities.

Ideal Situations for Ball Valve Usage

The quick, reliable sealing of ball valves makes them versatile and widely used in many different scenarios.

Emergency Shut-offs: Their quarter-turn action makes them perfect for gas lines or any system where a rapid shutdown might be needed for safety.

Frequent Cycling: In manufacturing processes where flow needs to be started and stopped regularly, a ball valve will outlast a gate valve.

Small-Scale Plumbing: They are the standard for residential shut-off valves for sinks, toilets, and water heaters due to their ease of use and reliability.

Maintenance and Care for Ball Valves and Gate Valves

Maintenance Tips for Ball Valves

Regular Cycling: If a ball valve is left in one position for too long, mineral deposits can build up and cause the ball to seize. It's good practice to cycle the valve (turn it from open to closed and back again) every few months to keep it operating smoothly.

Check for Leaks: Periodically inspect the valve stem packing for any signs of leakage. If a leak is detected, tightening the packing nut can often solve the problem. If not, the packing may need to be replaced.

Lubrication: While many modern ball valves have self-lubricating seats, some may require lubrication, especially in demanding applications. Check the manufacturer's recommendations.

Care Guidelines for Gate Valves

Lubricate the Stem: The threaded stem of a gate valve needs to be kept clean and lubricated to prevent corrosion and ensure smooth operation. This is especially important for valves located outdoors or in harsh environments.

Avoid Over-Tightening: When closing a gate valve, turn the handle until you feel firm resistance, and then stop. Over-tightening can damage the gate, seats, and stem, making it difficult to open the valve later and potentially compromising the seal.

Protect the Stem: For rising-stem gate valves, the exposed stem should be protected from physical damage and corrosion.

Signs of Wear: When to Replace Your Valves

Even with proper care, all valves will eventually wear out. Knowing the signs of failure can help you replace a valve before it causes a major problem.

Difficulty Operating: If a valve becomes very stiff or difficult to turn, it may be a sign of internal corrosion or scale buildup.

Visible Leaks: Any leakage from the valve body or around the stem that cannot be fixed by tightening the packing nut indicates that the valve's seals have failed.

Incomplete Shut-off: If the valve no longer stops the flow completely when closed, the internal sealing surfaces are likely damaged, and the valve should be replaced.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More