Exploring Control Valve Pneumatic Systems: Key Features and Their Practical Applications

In industrial settings, precision and reliability are paramount. From manufacturing lines to complex robotics, the ability to accurately control the flow of gases and air is fundamental. This is where pneumatic control valves come into play. These devices are the backbone of many automated systems, directing compressed air to power machinery with remarkable accuracy.

Understanding how these valves work is essential for anyone involved in industrial automation, engineering, or manufacturing. This guide will explore the core principles of pneumatic control valves, detailing their types, key features, and diverse applications. By the end, you'll have a clear picture of how these components drive efficiency and innovation across various industries and how to select the right system for your specific needs.

Understanding Pneumatic Control Valves

What are Pneumatic Control Valves?

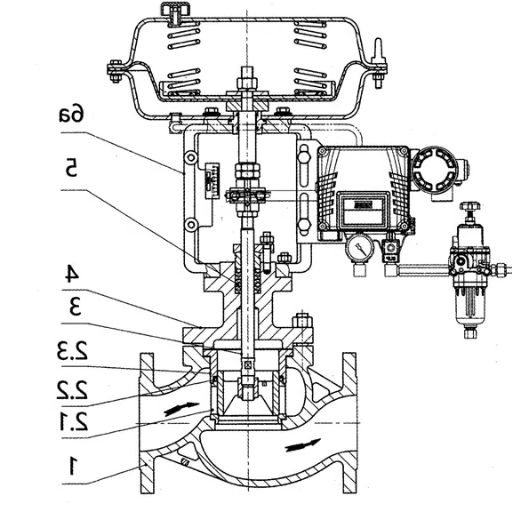

A pneumatic control valve is a mechanical device designed to regulate the passage of air or gas within a pneumatic circuit. Think of it as a traffic controller for air. By opening, closing, or partially obstructing pathways, these valves direct compressed air to where it's needed, such as powering an actuator, a cylinder, or another pneumatic tool. Their primary role is to start, stop, or change the direction of air flow in response to a signal. This signal can be manual (from an operator), mechanical (from a machine part), or electrical (from a solenoid).

How Pneumatic Valves Function in a System

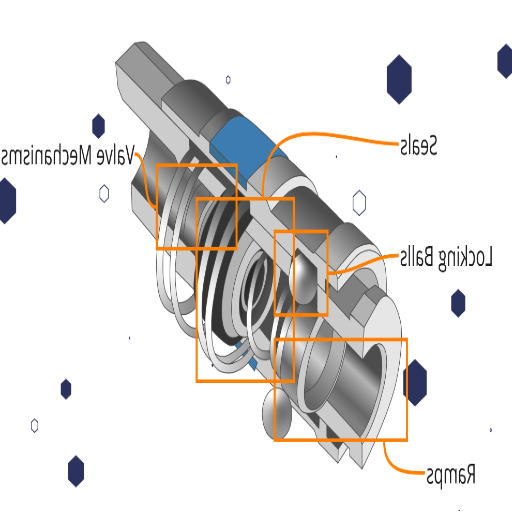

A pneumatic valve functions by manipulating the flow path of compressed air. Inside the valve, there are internal moving parts—such as spools, poppets, or diaphragms—that shift position to either block or open ports.

The process typically unfolds as follows:

Actuation Signal: The valve receives a signal to change its state. This could be an electrical current energizing a solenoid, a mechanical lever being pushed, or an operator pressing a button.

Internal Movement: The signal causes the internal mechanism to move. For instance, in a spool valve, a cylindrical spool slides within a bore. The lands (raised sections) on the spool block certain ports while the grooves allow air to pass between others.

Flow Redirection: As the internal parts move, the connections between the valve's ports change. This redirects the compressed air from the inlet port to a specific outlet port, which is connected to an actuator or another device. At the same time, it might open another port to allow used air to be exhausted from the system.

For example, to extend a double-acting pneumatic cylinder, the valve directs compressed air to the piston's base, pushing it forward. To retract it, the valve switches, sending air to the rod end of the piston and exhausting the air from the base. This simple, controlled action is the basis for countless automated tasks.

Types of Pneumatic Control Valves

Pneumatic control valves are categorized based on their function, design, and the number of ports and positions they have. The most common classification is based on their primary function: directional control, flow control, and pressure control.

Directional Control Valves: These are the most common type and are used to start, stop, and change the direction of air flow. They are identified by the number of ports (entry/exit points) and positions (the number of distinct flow paths the valve can provide). For example, a 5/2-way valve has five ports and two positions.

Flow Control Valves: These valves regulate the speed of pneumatic actuators by controlling the rate of air flow. A needle valve is a common type, allowing for fine adjustment of the flow rate.

Pressure Control Valves: These are essential for safety and efficiency. They manage the pressure within the system. This category includes pressure relief valves (which vent excess pressure), pressure regulators (which maintain a constant output pressure), and sequence valves (which activate parts of a circuit in a specific order based on pressure).

Another way to classify valves is by their actuation method, which includes:

Solenoid-operated valves: Use an electric coil to actuate the valve.

Mechanically-operated valves: Actuated by physical contact with a machine part, like a lever or roller.

Manually-operated valves: Controlled by a human operator via buttons, levers, or foot pedals.

Pilot-operated valves: Use air pressure itself to shift the valve's position.

Key Features of Pneumatic Control Valves

Directional Control in Pneumatic Systems

Directional control is the primary function of many pneumatic valves. This is defined by the valve's "ways" and "positions."

Ways (Ports): This refers to the number of active connection points for air to flow in or out. A 2-way valve has an inlet and an outlet. A 3-way valve adds an exhaust port. 4-way and 5-way valves are common for controlling double-acting cylinders, as they have ports for two actuator connections and exhausts.

Positions: This indicates the number of distinct operational states the valve can be in. A 2-position valve, for instance, has two states, such as "on" and "off" or "extend" and "retract." A 3-position valve typically includes a neutral or center position, which can block all ports or vent all ports, providing additional control over the actuator.

The notation "5/2" means five ways (ports) and two positions, a common configuration for controlling a double-acting cylinder.

Pressure Management and Control Solutions

Maintaining the correct pressure is vital for the safety, efficiency, and longevity of a pneumatic system.

Operating Pressure Range: Every valve is designed to work within a specific range of air pressures. Operating outside this range can lead to malfunction or damage.

Flow Rate (Cv): The flow coefficient, or Cv, measures a valve's capacity to pass air. A higher Cv value means the valve can allow more air to flow through it at a given pressure, which translates to faster actuator speeds. Choosing a valve with the appropriate Cv is essential to meet the performance requirements of the system.

Advantages of Using Pneumatic Control Valves

Pneumatic systems, and the control valves that govern them, offer several distinct advantages over hydraulic or electric systems, making them the preferred choice for many industrial applications.

Reliability and Durability: Pneumatic components are known for their long service life and robustness. They can operate in harsh environments with dust, moisture, and temperature fluctuations where electronic systems might fail.

Safety: Compressed air is inherently safer than hydraulic fluid, which can be flammable and messy if it leaks. Air leaks do not contaminate the environment. Furthermore, pneumatic systems can be designed to be intrinsically safe for use in explosive atmospheres.

Cost-Effectiveness: The initial cost of pneumatic components is often lower than hydraulic or electric equivalents. Compressed air is also a relatively inexpensive and readily available power source.

Simplicity: The design and operation of pneumatic systems are generally straightforward, making them easier to install, operate, and maintain. Troubleshooting is often simpler compared to complex electronic circuits.

Speed: Pneumatic actuators can operate at very high speeds, making them ideal for applications requiring rapid, repetitive motion, such as pick-and-place robotics and assembly lines.

Applications of Pneumatic Control Valves

Industrial Automation and Control

In the realm of industrial automation, pneumatic valves are indispensable. They control the movement of products on conveyor belts, operate clamps that hold workpieces in place, and power the machinery that sorts, packages, and assembles goods. Their rapid response times and ability to perform millions of cycles without failure make them perfect for high-volume production environments.

Air Control Valves in Manufacturing Processes

Manufacturing processes rely heavily on pneumatic control. Examples include:

Food and Beverage: In packaging plants, pneumatic valves control the mechanisms that fill bottles, seal packages, and stack boxes. The clean nature of compressed air is a significant advantage in these hygienic environments.

Automotive: Assembly lines use pneumatic tools for everything from tightening bolts to positioning large components like doors and windshields. Pneumatic clamps securely hold chassis parts during welding.

Pharmaceuticals: Pneumatic systems handle delicate tasks like sorting pills, capping vials, and operating blister packaging machines, where precision and contamination control are critical.

Use Cases in Robotics and Actuation

Robotics is another field where pneumatic actuation shines. Pick-and-place robots often use pneumatic grippers to handle objects. The grippers, controlled by pneumatic valves, can provide a firm but gentle grasp, suitable for handling everything from heavy metal parts to fragile electronic components. The high speed and simple control of pneumatic cylinders make them ideal for creating rapid, linear movements in robotic arms and other automated machinery.

Choosing the Right Pneumatic System

Factors to Consider for System Requirements

Before selecting a valve, you must first define the needs of the application. Key factors include:

Actuator Type: Are you controlling a single-acting cylinder, a double-acting cylinder, a pneumatic motor, or a gripper? The actuator determines the type of directional control valve needed.

Speed of Operation: How fast does the actuator need to move? This will determine the required flow rate (Cv) of the valve and the size of the tubing.

Load and Force: The amount of force the actuator must generate will dictate the required air pressure and the cylinder's bore size. The pressure regulator must be able to supply this pressure consistently.

Operating Environment: Will the valve be exposed to moisture, corrosive chemicals, extreme temperatures, or explosive atmospheres? This will influence the required material (e.g., stainless steel vs. aluminum) and protection rating (e.g., IP rating).

Control Signal: How will the valve be actuated? The choice between solenoid, manual, or mechanical actuation depends on whether the system is automated or operator-controlled.

Port Sizes and Mounting Options

Practical considerations like port size and mounting are also crucial.

Port Sizes: The size of the valve's ports must match the tubing size to ensure adequate air flow without creating bottlenecks. Port sizes are typically specified in inches (e.g., 1/4", 1/2") or millimeters.

Mounting Options: Valves can be mounted in-line (directly connected to the air lines) or on a manifold. Manifold mounting is often preferred in complex systems as it centralizes the valves, simplifies plumbing, reduces potential leak points, and makes maintenance easier.

Customizing Solutions for Automation Needs

Often, standard off-the-shelf components may not perfectly fit a unique automation challenge. Many suppliers offer customization options, allowing you to specify materials, seals, actuation types, and electrical connectors to build a valve that precisely meets your application's demands. Working with an experienced supplier can help you design a tailored pneumatic solution that optimizes performance and reliability.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More