A Comprehensive Guide to Butterfly Valve Wafer Type: Features and Advantages

In industrial systems, controlling fluid flow is a critical function. Among the various types of valves available, the butterfly valve stands out for its simplicity, cost-effectiveness, and wide range of applications. This guide provides a comprehensive overview of the butterfly valve, with a specific focus on the wafer type, exploring its features, advantages, and operational dynamics.

Understanding how these components work is essential for engineers, technicians, and project managers involved in the design, operation, and maintenance of fluid control systems. From water treatment plants to chemical processing facilities, the correct valve selection impacts efficiency, safety, and operational costs. This article will equip you with the knowledge to make informed decisions about using butterfly valve wafer types in your specific applications.

Understanding the Butterfly Valve

What is a Butterfly Valve?

A butterfly valve is a type of quarter-turn valve used to regulate or isolate fluid flow. The "butterfly" is a disc mounted on a rotating shaft. When the valve is fully closed, the disc is perpendicular to the flow, blocking the passageway. When the valve is fully open, the disc is parallel to the flow, allowing for almost unrestricted passage of the fluid. The valve can also be opened incrementally to throttle or regulate flow.

Due to their simple design, butterfly valves are compact, lightweight, and less expensive than many other valve types, especially in larger pipe diameters. They offer quick shut-off capabilities, as a 90-degree turn of the handle moves the valve from fully open to fully closed.

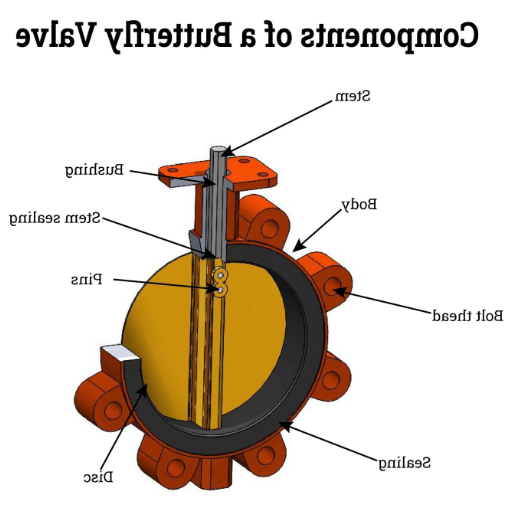

Key Components of a Butterfly Valve

A butterfly valve consists of four main components:

Body: This is the main part of the valve that fits between the pipe flanges. It houses the internal components.

Disc: This component, often called the butterfly, is responsible for controlling the flow. It rotates within the valve body to open or close the passage.

Stem: The stem connects the disc to the actuator (like a handle or lever) on the outside of the valve. It transmits the rotational motion from the actuator to the disc.

Seat: The seat is a liner, often made of an elastomer or polymer, that provides the seal between the disc and the valve body. This ensures a tight shut-off and prevents leakage when the valve is closed.

Types of Butterfly Valves

Butterfly valves are generally categorized based on their body style and how they connect to the piping system. The three primary types are:

Wafer Type: This is the most common and economical style. It is designed to be clamped between two pipe flanges.

Lug Type: This valve has threaded inserts (lugs) around the body that allow it to be installed into a system using bolts. This design allows for dead-end service, meaning one side of the piping can be removed while the valve remains in place.

Flanged Type: This type has flanges on both ends of the valve body, which are bolted directly to the matching flanges on the pipes. This is a less common and more expensive design.

Wafer Style Butterfly Valves

What is a Wafer Butterfly Valve?

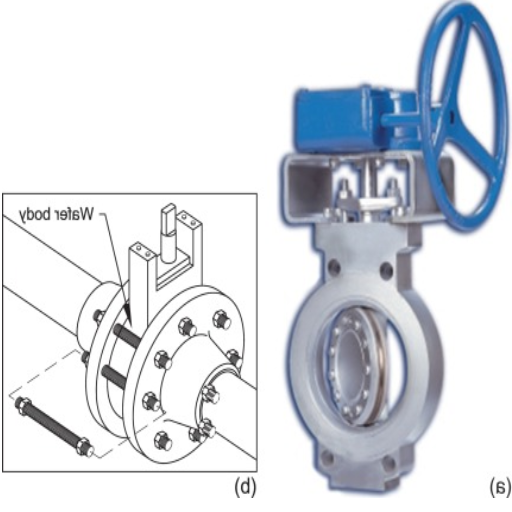

A wafer butterfly valve is designed to be sandwiched between two pipe flanges. It is held in place by the tension from the bolts or studs that run from one flange to the other, passing through holes in the valve's body. This design does not require its own set of bolts for installation, which contributes to its lighter weight and lower cost.

The face-to-face dimension of a wafer valve is very narrow, making it an excellent choice for systems where space is limited. The sealing is typically achieved by a resilient seat, which also functions as a gasket between the valve body and the pipe flanges.

Advantages of Wafer Style

The wafer style butterfly valve offers several key benefits:

Cost-Effective: They are generally less expensive to manufacture and purchase compared to lug or flanged types, especially in larger sizes.

Lightweight and Compact: The minimalist design results in a smaller and lighter valve, which simplifies handling, installation, and support requirements for the piping system.

Easy Installation: The process of clamping the valve between two flanges is quick and straightforward, reducing installation time and labor costs.

Versatility: Wafer valves can be used with a variety of fluids and are suitable for a wide range of pressures and temperatures, depending on the materials used for the body, disc, and seat.

Low Maintenance: With fewer parts and a simple construction, these valves require minimal maintenance over their service life.

Applications of Wafer Butterfly Valves

Thanks to their versatility and economic advantages, wafer butterfly valves are used extensively in numerous industries and applications, including:

Water and Wastewater Treatment: Used for flow control in treatment plants, distribution systems, and pumping stations.

HVAC Systems: Ideal for regulating the flow of water and other fluids in heating, ventilation, and air conditioning systems.

Chemical Processing: Suitable for handling a variety of chemicals, provided the valve materials are compatible with the media.

Food and Beverage: Stainless steel versions with food-grade seats are used in processing lines for sanitary applications.

Power Generation: Used in cooling water systems and other auxiliary services in power plants.

General Industrial Services: Their broad applicability makes them a staple in countless manufacturing and processing facilities.

Material Considerations for Butterfly Valves

Choosing the Right Material: Stainless vs. Other Materials

The materials for the body and disc are primary considerations.

Stainless Steel: This is a popular choice for its excellent corrosion resistance, durability, and suitability for high-purity applications like food, beverage, and pharmaceuticals. Grades like 304 and 316 are common. 316 stainless steel, with its added molybdenum, offers superior resistance to chlorides and other corrosive substances.

Ductile Iron: This material provides high strength and durability at a lower cost than stainless steel. It is often used for the body in general industrial applications, particularly for water and air services. The disc may be coated or made of a more resistant material.

Carbon Steel: Offers high strength and is suitable for high-temperature and high-pressure applications. However, it has lower corrosion resistance compared to stainless steel and may require protective coatings.

Plastic (PVC, CPVC): These materials are lightweight and offer excellent resistance to a wide range of chemicals. They are commonly used in chemical processing, water treatment, and irrigation systems where metal corrosion is a concern.

Understanding EPDM Seats and Their Benefits

The seat is a critical component for achieving a tight seal. The material of the seat must be compatible with the process fluid and temperature.

EPDM (Ethylene Propylene Diene Monomer): This is one of the most common and versatile seat materials. EPDM offers excellent resistance to water, steam, alcohols, and ketones. It has a wide temperature range, typically from -30°F to 250°F (-34°C to 121°C). Its durability and cost-effectiveness make it a standard choice for many water and HVAC applications.

Buna-N (Nitrile): This material is well-suited for petroleum-based oils, fuels, and solvents. It is a common choice in the oil and gas industry.

Viton (FKM): Viton provides excellent resistance to a broad range of chemicals, acids, and high temperatures, making it suitable for more aggressive chemical processing applications.

PTFE (Teflon): PTFE is known for its exceptional chemical resistance and ability to handle both very high and very low temperatures. It is often used in a two-piece seat design or as a liner for the valve body.

Resilient Seated vs. Non-Resilient Seated

Butterfly valves can also be classified based on their seat design:

Resilient Seated: This is the most common design for wafer butterfly valves. It uses a soft, elastomeric seat (like EPDM or Buna-N) that provides a bubble-tight seal. The disc compresses into the seat when closed. These are generally used for lower pressure and temperature applications.

High-Performance (Non-Resilient or Metal Seated): These valves use a more rigid seat, often made of metal (like stainless steel) or a hard polymer (like PTFE). They are designed for more demanding applications involving high pressures, high temperatures, or abrasive media. They often feature a double or triple offset design to reduce seat wear and lower operating torque.

Operational Aspects of Wafer Butterfly Valves

How Wafer Butterfly Valves Operate

The valve operates through a 90-degree rotation of the disc.

Closing: The actuator turns the stem, which rotates the disc to a position perpendicular to the flow. In a resilient seated valve, the edge of the disc presses firmly into the soft seat, creating a tight seal.

Opening: The actuator rotates the disc back to a position parallel to the flow. This allows the fluid to pass through the valve with minimal obstruction.

Throttling: The valve can be positioned at any angle between fully open and fully closed to regulate the flow rate. However, it's important to note that throttling can cause turbulence and disc vibration, which may lead to wear over time.

Size and Flange Considerations

Butterfly valves are available in a wide range of sizes, from as small as 1 inch to over 100 inches in diameter.

Sizing: The valve size should match the nominal pipe size (NPS) of the system it is being installed in.

Flange Compatibility: Wafer valves are designed to fit between flanges of different standards, such as ANSI/ASME, DIN, and JIS. It is crucial to ensure that the valve is compatible with the flange standard being used in the piping system to ensure a proper fit and seal. The alignment of the bolt holes is a key factor.

Lever Mechanisms and Their Usage

The actuator is the mechanism used to open and close the valve. For smaller butterfly valves (typically up to 12 inches), manual actuators are common.

Lever Handle: This is the simplest form of actuator. A lever is attached directly to the valve stem. Pushing the lever 90 degrees moves the valve from open to closed. Lever handles often include a locking mechanism or a notched plate that allows the valve to be locked in various positions for throttling.

Gear Operator: For larger valves, the torque required to open or close the valve can be significant. A gear operator uses a handwheel connected to a gearbox to multiply the force applied by the operator, making it easier to actuate the valve.

Automated Actuators: In many industrial processes, valves need to be operated remotely or as part of an automated control loop. In these cases, electric, pneumatic, or hydraulic actuators are used. These actuators can be controlled by a signal from a control system to open, close, or modulate the valve.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More