Butterfly Valve vs Gate Valve: Key Differences and Choosing the Right Option

In industrial and commercial fluid systems, selecting the right valve is critical for operational efficiency and safety. Among the most common types are shutoff valves, which are essential for controlling flow. Two of the most frequently used shutoff valves are the butterfly valve and the gate valve. While both serve to start and stop flow, their designs, performance characteristics, and ideal applications differ significantly.

This guide provides a comprehensive comparison of butterfly valves versus gate valves. We will explore their design, operation, and specific uses to help you understand which valve is the optimal choice for your system's requirements. By understanding their key differences, you can make an informed decision that enhances performance and cost-effectiveness.

An Introduction to Shutoff Valves

What are Shutoff Valves?

Shutoff valves, also known as isolation valves, are designed to start or stop the flow of fluid in a pipeline. Their primary function is to provide a positive seal to prevent leakage when closed. These valves are not typically intended for regulating or throttling flow, although some types can perform this function with limitations. They are a fundamental component in nearly every fluid-handling system, from simple residential plumbing to complex industrial processing plants.

Importance of Choosing the Right Valve

Selecting the correct shutoff valve is crucial for several reasons:

System Performance: The right valve ensures the system operates as designed, with minimal pressure drop and reliable flow control.

Safety: A properly selected valve prevents leaks and catastrophic failures, protecting personnel, equipment, and the environment.

Longevity and Maintenance: Choosing a valve suited for the specific media, temperature, and pressure conditions will extend its service life and reduce maintenance requirements.

Cost-Effectiveness: An appropriate valve minimizes initial investment and long-term operational costs, including energy consumption and repair expenses.

Overview of Valve Types

Shutoff valves come in various designs, each with unique characteristics. Besides butterfly and gate valves, other common types include ball valves, globe valves, and plug valves. This guide will focus specifically on butterfly and gate valves, two of the most prevalent choices in industrial settings.

Understanding Butterfly Valves

Design and Operation

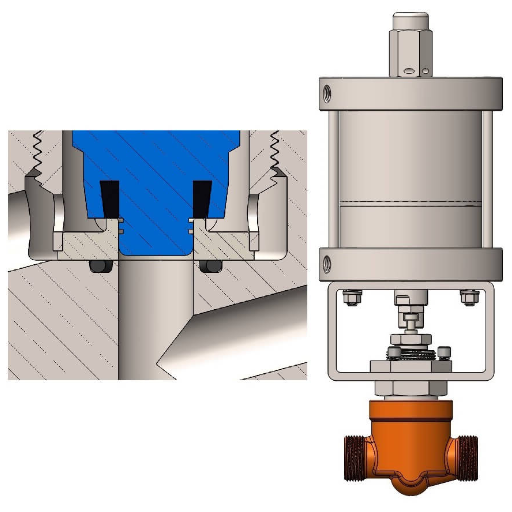

A butterfly valve consists of a circular body, a disc mounted on a central stem, and a seat. The operation is straightforward:

In the closed position, the disc is perpendicular to the flow, and its edge is sealed against the seat, blocking the fluid path.

To open the valve, the stem is rotated 90 degrees (a quarter-turn), which turns the disc to be parallel with the flow, allowing fluid to pass.

This quarter-turn action makes butterfly valves fast to operate, either manually with a lever or automatically with an actuator. The disc remains within the flow path even when fully open, which can cause a slight pressure drop.

Applications of Butterfly Valves

Butterfly valves are used across numerous industries due to their compact and lightweight design. Common applications include:

Water and Wastewater Treatment: Their ability to handle large volumes of fluid and some slurries makes them ideal for municipal water systems.

HVAC Systems: Used in heating, ventilation, and air conditioning to control the flow of water and other fluids.

Chemical Processing: Available in various materials, they can handle corrosive chemicals, though compatibility must be verified.

Food and Beverage: Sanitary versions are used for processing liquids and semi-solids.

Bulk Material Handling: They can control the flow of dry bulk materials like powders and granules.

Advantages of Using Butterfly Valves

Butterfly valves offer several distinct benefits:

Compact and Lightweight: They require less space and structural support than gate valves, especially in large pipe diameters. This reduces installation costs.

Fast Operation: The 90-degree turn from fully open to fully closed allows for rapid shutoff.

Lower Cost: Butterfly valves are generally less expensive to manufacture and purchase, particularly in larger sizes.

Versatility: They are suitable for liquids, gases, and slurries, and can be used for some throttling applications.

Exploring Gate Valves

Design and Functionality

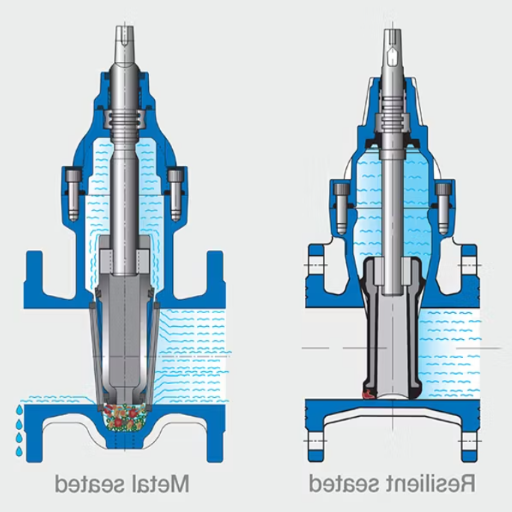

A gate valve operates by lifting a rectangular or circular gate out of the path of the fluid. The key components are the body, bonnet, stem, and the gate itself.

In the fully open position, the gate is completely withdrawn into the valve bonnet. This creates a straight, full-bore opening that is the same diameter as the pipe, resulting in minimal pressure drop.

In the closed position, the gate is lowered to block the flow path, sealing tightly against two seats.

Operation requires multiple turns of a handwheel or actuator, making gate valves slower to operate compared to butterfly valves. This slow operation can be advantageous in preventing water hammer in certain systems.

Common Uses of Gate Valves

Gate valves are best suited for applications where a straight-line flow and minimal restriction are critical. Their uses include:

Oil and Gas Industry: Widely used in pipelines for crude oil, natural gas, and refined products where low pressure drop is essential.

Power Plants: Employed in high-pressure and high-temperature services, such as steam lines.

Manufacturing: Used for general industrial applications involving liquids and gases.

Water Supply: Often found in large-diameter water mains where full flow is necessary.

Benefits of Gate Valves

The primary advantages of gate valves include:

Minimal Pressure Drop: When fully open, they provide an unobstructed flow path, leading to very low friction loss.

Tight Sealing: They can provide a bubble-tight shutoff, making them reliable for isolation purposes.

High-Pressure and High-Temperature Capability: Gate valves are well-suited for demanding service conditions.

Bidirectional Flow: Most designs allow for flow in either direction.

Butterfly Valve vs Gate Valve: Key Differences

Comparative Analysis of Performance

Sealing: Gate valves generally provide a tighter, more reliable seal, especially in high-pressure applications. The gate's design allows it to seal firmly against its seats. Butterfly valves, particularly concentric designs, rely on the resilience of the seat material, which can wear over time. However, high-performance butterfly valves (double and triple offset) offer excellent sealing capabilities, rivaling gate valves.

Pressure Drop: Gate valves excel here. With the gate fully retracted, there is no obstruction in the flow path, resulting in almost zero pressure drop. The disc of a butterfly valve remains in the flow, causing a slight pressure drop even when fully open.

Operation Speed: Butterfly valves are significantly faster to operate due to their quarter-turn design. This can be critical in emergency shutoff situations. Gate valves require multiple turns, making them slow but also less prone to causing hydraulic shock (water hammer).

Cost-Effectiveness

Initial Cost: Butterfly valves are typically more affordable, especially in larger pipe sizes (above DN 200 or 8 inches). Their simpler, lighter design requires less material and is easier to manufacture.

Installation Cost: The compact and lightweight nature of butterfly valves reduces installation time and costs. They require less heavy equipment for handling and less structural support for the pipeline.

Maintenance Cost: Both valve types require regular maintenance. However, the seats of butterfly valves can be easier and cheaper to replace than the seats of a gate valve, which may require removing the entire valve from the line.

Throttle Capabilities

Butterfly Valves: These valves can be used for throttling or regulating flow. However, because the disc is always in the flow, continuous throttling can cause turbulence and uneven wear on the disc and seat, potentially compromising its shutoff ability. They are generally suitable for applications where precise control is not the primary requirement.

Gate Valves: Gate valves are not recommended for throttling. When partially open, the high fluid velocity across the gate and seat can cause significant erosion (known as flow-induced vibration) and damage, preventing the valve from sealing properly when fully closed. They should only be used in the fully open or fully closed positions.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More