How a Butterfly Valve with Actuator Enhances Efficiency in Fluid Control Applications

Efficient fluid control is a critical component in countless industrial and commercial systems. From massive water treatment plants to intricate chemical processing lines, the ability to precisely manage the flow of liquids and gases is paramount for safety, efficiency, and cost-effectiveness. The butterfly valve with an actuator stands out as a superior solution, offering rapid operation, reliable sealing, and automated control that modern systems demand.

This guide will explore the mechanics and advantages of using a butterfly valve with an actuator. We will cover the fundamental components, their operational benefits, and how they compare to other valve types. You will also find detailed information on the different kinds of actuators, best practices for installation and maintenance, and a troubleshooting guide to keep your systems running smoothly. By the end, you'll have a comprehensive understanding of why this combination is a go-to choice for engineers and system designers seeking optimal performance in fluid control applications.

An Introduction to Butterfly Valves

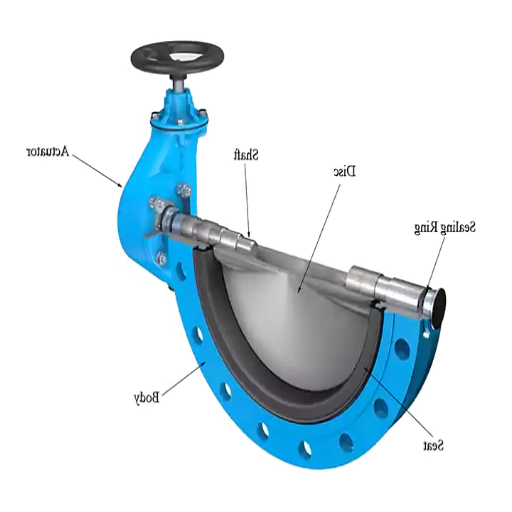

What Is a Butterfly Valve?

A butterfly valve is a type of quarter-turn valve used to regulate or isolate fluid flow. Its design is straightforward: a metal disc, often called the "butterfly," is mounted on a rod. When the valve is closed, the disc is perpendicular to the flow, creating a seal against a seat within the valve body. To open the valve, the rod rotates the disc a quarter turn (90 degrees), positioning it parallel to the flow and allowing the fluid to pass through with minimal obstruction.

This simple mechanism makes butterfly valves lightweight, compact, and less expensive than many other valve types, especially in larger pipe diameters. They offer quick shut-off capabilities and can be used for both on/off and throttling services, though they are most effective when fully open or fully closed.

Common Applications of Butterfly Valves

The versatility and efficiency of butterfly valves make them suitable for a broad spectrum of industries and applications. Their ability to handle large volumes of fluids and slurries is a key advantage.

Common uses include:

Water and Wastewater Treatment: Used in filtration systems, backflow prevention, and distribution lines due to their ability to manage large flow rates.

Chemical Processing: Available in various corrosion-resistant materials, they are ideal for controlling the flow of chemicals, acids, and other aggressive media.

HVAC Systems: Their compact size and quick operation are beneficial for controlling air and water flow in heating, ventilation, and air conditioning units.

Food and Beverage Production: Hygienic butterfly valves made from stainless steel are used to control the flow of liquids in processing lines, ensuring sanitary conditions.

Oil and Gas: Employed in pipelines and processing facilities for managing the flow of hydrocarbons, though often in less critical, lower-pressure applications.

The Role of Actuators in Modern Fluid Control

While a manual butterfly valve is effective, adding an actuator transforms it into a powerful component of an automated system. An actuator is a device that uses a power source to operate the valve, eliminating the need for manual intervention.

The importance of actuators cannot be overstated in modern industrial processes. They enable remote operation, which is crucial for valves located in hazardous or inaccessible areas. Furthermore, actuators provide precise, repeatable control that is essential for maintaining consistent process conditions, improving product quality, and enhancing operational safety. By integrating with control systems like PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control and Data Acquisition), actuated valves can respond automatically to changes in pressure, temperature, or flow rate.

The Actuated Butterfly Valve: How It Works

Advantages of Actuated Butterfly Valves

The integration of an actuator brings numerous benefits that enhance system performance:

Increased Efficiency and Speed: Actuators operate the valve much faster than a manual lever or gearbox, which is critical in emergency shutdown situations or in processes requiring rapid cycling.

Remote and Automated Control: Operators can control valves from a central location, improving safety and reducing labor costs. Automation allows the system to run with minimal human oversight.

Precision and Repeatability: Actuators provide consistent positioning, ensuring that flow rates are maintained accurately every time. This is vital for processes that depend on precise ingredient mixing or temperature regulation.

Enhanced Safety: By enabling remote operation, actuators keep personnel away from potentially dangerous environments, such as those with high pressures, extreme temperatures, or hazardous materials.

Comparing Actuated Butterfly Valves and Ball Valves

While both butterfly valves and ball valves are quarter-turn devices, they have distinct differences. A ball valve uses a spherical ball with a hole through it to control flow.

Sealing: Ball valves generally offer a tighter, bubble-proof seal, making them superior for applications where zero leakage is critical, like in natural gas pipelines. However, modern high-performance butterfly valves provide excellent sealing capabilities suitable for most industrial needs.

Flow Characteristics: Butterfly valves have a disc that remains in the flow path even when fully open, which can cause a slight pressure drop. Ball valves offer an unobstructed path, resulting in minimal pressure loss.

Cost and Size: For larger pipe diameters (typically 3 inches and above), butterfly valves are significantly lighter, more compact, and more economical than ball valves.

The choice between them often depends on the specific application requirements, including pressure, temperature, media type, and budget.

Types of Actuators for Butterfly Valves

Pneumatic Actuators: Features and Benefits

Pneumatic actuators use compressed air to generate the force needed to turn the valve. They are known for their reliability, high speed, and cost-effectiveness.

Mechanism: They typically use a piston or a diaphragm to convert air pressure into linear or rotary motion. They can be either single-acting (spring-return) or double-acting. A spring-return actuator uses air to open the valve and a spring to close it (or vice versa), providing a fail-safe position in case of air supply loss. A double-acting actuator uses air for both opening and closing.

Benefits:

High Speed and Torque: They can operate large valves very quickly.

Durability: Their simple design makes them robust and long-lasting with minimal maintenance.

Safety: They are intrinsically safe for use in explosive or flammable environments since they do not use electricity.

Cost-Effective: Pneumatic actuators often have a lower initial cost compared to electric actuators of a similar size.

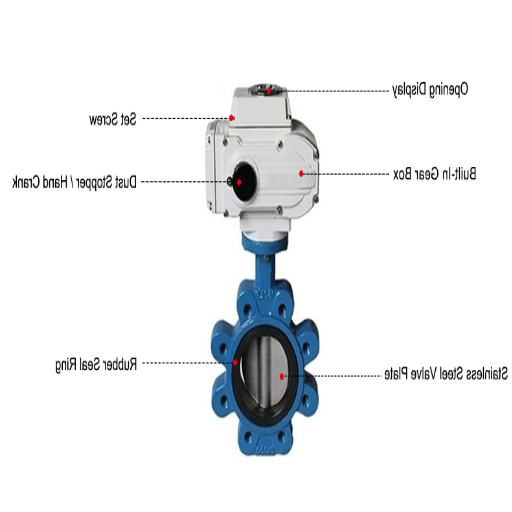

Electric Actuators: Efficiency and Control

Electric actuators use an electric motor to generate torque. They are praised for their precise control, energy efficiency, and ease of integration into digital control systems.

Mechanism: An electric motor drives a gear train that converts the high-speed, low-torque output of the motor into the low-speed, high-torque motion required to operate the valve.

Benefits:

Precise Positioning: They can be controlled with extreme accuracy, making them ideal for throttling and complex process control.

Energy Efficiency: They only consume power when moving the valve, unlike pneumatic systems that require a constantly running air compressor.

Easy Installation: They only need electrical wiring, eliminating the need for air lines, filters, and regulators.

Advanced Diagnostics: Many modern electric actuators offer diagnostic capabilities, providing feedback on valve position, torque, and operational health.

Choosing the Right Actuator

Selecting the correct actuator depends on several factors:

Available Power Source: Is compressed air readily available, or is electricity the more convenient option?

Operating Environment: Is the area hazardous, requiring an explosion-proof design? Pneumatic actuators are often preferred in such cases.

Control Requirements: Is simple on/off control sufficient, or is precise throttling needed? Electric actuators excel at precision.

Fail-Safe Needs: Is it critical for the valve to move to a specific position (open or closed) upon power failure? Spring-return pneumatic actuators provide a simple and reliable fail-safe solution.

Speed of Operation: Pneumatic actuators are generally faster than electric actuators.

Installation and Maintenance Best Practices

Installation Best Practices

Inspect Before Installing: Check the valve and actuator for any damage that may have occurred during shipping.

Clean the Pipes: Ensure the pipeline is free of debris, weld slag, or other foreign materials that could damage the valve seat or disc.

Align the Flanges: The valve should be installed between properly aligned pipe flanges. Misalignment can cause stress on the valve body, leading to leakage.

Position the Disc Correctly: For most installations, the valve should be installed with the disc in a partially open position to prevent the seat from being pinched or damaged during bolt tightening.

Tighten Bolts Evenly: Use a crisscross pattern to tighten the flange bolts gradually and evenly to ensure a uniform seal.

Regular Maintenance for Optimal Performance

Visual Inspection: Regularly check the assembly for any signs of external corrosion, leaks, or damage to the actuator or wiring.

Cycle the Valve: If a valve remains in one position for an extended period, it should be cycled (opened and closed) periodically to prevent the disc from seizing.

Check for Leaks: Inspect the flange connections and the valve stem for any signs of leakage.

Lubrication: Follow the manufacturer's recommendations for lubricating the actuator's moving parts and the valve's stem assembly.

Actuator Maintenance: For pneumatic actuators, check the air supply for moisture and contaminants. For electric actuators, ensure all electrical connections are secure and protected from the elements.

Common Issues and Troubleshooting

Valve Not Sealing Properly: This could be due to a damaged seat, a misaligned disc, or debris in the valve. The valve may need to be removed, inspected, and repaired or replaced.

Actuator Fails to Operate: For pneumatic actuators, check the air supply pressure and the solenoid valve. For electric actuators, verify the power supply and check for blown fuses or tripped breakers.

Sluggish Operation: This may be caused by insufficient air pressure (pneumatic), low voltage (electric), or excessive friction in the valve due to wear or lack of lubrication.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More