Conductivity Sensor & Transmitter: What is a conductivity transmitter used for?

Conductivity sensors have a critical function within nearly every industry, from water purification to chemical production, in controlling and monitoring fluid properties. So how do these sensors work, and why are they so essential? This blog entry zooms in deep on the very much fascinating science coursing behind conductivity sensors and their transmitters and takes a study spree through the key principles that make these devices so effective. Whether you are a professional or just an inquisitive mind despre industrial measurement technology, this article will enrich you with a few insights about how conductivity sensors work and where they find their critical applications. So get ready to unmask the functioning of these very important tools and find out how they impact the changes in efficiency, safety, and quality control.

Understanding Conductivity Sensors

Conductivity sensors measure how well a liquid can conduct the flow of current. They work by applying a voltage across two electrodes and measuring the current flow. At this point, the current that flows is determined by the concentration in conductive ions present within the compound in question, some of which may be salts, acids, or bases. It presents itself as a swift method for evaluating a solution's levels of purity or concentration, positioning conductivity sensors as implicated in the water treatment, chemical manufacturing, and food processing industries.

Definition and Working Principle of Conductivity Sensors

These sensors have myriad practical applications owing to the ability to provide instantaneous data pertaining to the ionic content of any solution. Some of the prominent industries where they are most sought after include:

Water Treatment and Monitoring

Conductivity sensors are an important consideration in the evaluation of water quality for potable water, wastewater, and industrial process waters. The Environmental Protection Agency (EPA) regulates that maintaining proper conductivity levels is imperative to ensure that water does not come with excessive dissolved salts and contaminants attached to it. For instance, in desalination plants, conductivity sensors check the salt content of the output water to establish the effectiveness of reverse osmosis systems.

Chemical Processing

Chemistry has so many conductivity sensors controlling chemical concentrations. For instance, concentrations must be maintained to strict tolerances in caustic-soda or sulfuric-acid manufacturers to ensure safety and quality. Sensors allow processes to evolve depending on real-time feedback and satisfy industry requirements.

Food and Beverage

Conductivity sensors are crucial for quality control in beverage, dairy, and processed food production. During cleaning-in-place (CIP) cycles, they monitor the cleaning chemicals' concentration to maintain appropriate hygiene levels while minimizing wastage.

Pharmaceuticals

To meet regulatory compliance, high levels of precision are required in pharmaceutical production. However, conductivity monitoring is necessary to ensure WFI purity and process consistency. For example, USP defines conductivity ranges for purified water as well as for WFI used in drug manufacture.

Data of Conductivity Monitoring

Optimal Ranges: Each application has its own needed conductivity range. For example:

Pure water has a conductivity usually below 0.2 µS/cm.

Seawater measures up to about 50,000 µS/cm being highly saline.

Industrial wastewater varies much, in the range of 500 to 5,000 µS/cm, dependent on pollutants in it.

Technological Advancements: Modern conductivity sensors are incorporated with advanced features such as temperature compensation, digital interfaces, or compatibility with industrial IoT platforms. Such integrations enhance the data accuracy and provide opportunities for remote monitoring and control-a trend observed more and more in smart factories.

Market Trends: According to a report by Grand View Research published in 2023, the global conductivity sensor market was sized at more than $2.5 billion and is expected to generate a CAGR of 5.6% in the period from 2023 to 2030. Such growth is accounted for by the ever-growing demand for water treatment solutions and progress in sensor technologies.

The wide applicability and trusted nature of conductivity sensors make them always present in industrial processes for ensuring efficiency, regulatory compliance, and environmental sustainability.

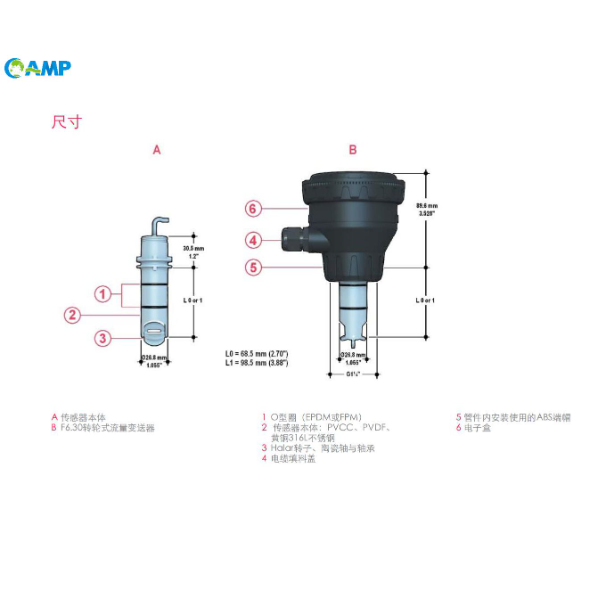

Key Components: Probes and Transmitters

Probes and Transmitters in Detail

For conductivity sensors, two main components exist: probes and transmitters, with their own particular roles in the instrument for accurate and reliable measurements. Probes are generally made out of hard materials like stainless steel or titanium to withstand aggressive environments with varying chemical compositions. Probes today have better sensitivity and durability to precisely detect ion concentrations in liquids.

The transmitter evaluates the signal from the probe and delivers a measurement in standard units to the operator. Modern transmitters will have digital interfaces, connectivity options such as Bluetooth and Wi-Fi, and the ability to be integrated into industrial systems such as SCADA. Moreover, the field is also advancing towards smart sensors garbed with diagnostic and predictive maintenance features, thereby providing greater efficiency to the end-user.

Market Trends and Applications

Latest data shows that the use of conductivity sensors is being introduced into industries. The food and beverage industry is, otherwise, expected to be a major growth market for conductivity sensors due to quality standards, production processes requiring accurate control, and so forth. On the other hand, pharmaceutical sectors growing at a fast pace use these sensors to comply with regulations and maintain the purity of active ingredients.

According to recent research, Asia-Pacific turns into the fastest market growing in conductivity sensors because of increased investment in the building of wastewater management infrastructure, on industrial automation, and more stringent environmental regulations. China and India, more particularly, are at the forefront by sharing a large chunk of this growth.

Environmental Feedback and Prospects for New Innovations

Newer improvements shall be targeted to render conductivity sensor classy and eco-friendly. Sensing systems shall integrate IoT and AI to let them offer real-time analytics so that industries could make faster—yet informed—decisions. In addition, an industry moving toward greener processes would enforce manufacturers to adopt greener designs so that sensor production and operation would have a reduced ecological footprint.

Worldwide conductivity sensor market still is one to watch for its adaptability to technological innovations alongside changing demands of industries, making sure of its growth and existence in powers within sectors.

How Conductivity Meters Work

The conductivity meters measure the solution's ability to conduct electricity: the conductivity is usually strictly dependent on the concentration of ions present in the solution under test. Hence, these instruments generally consist of a probe having electrodes that apply some voltage to the solution; depending on the strength of the resultant current, the conductivity, taken as a measure of the flow of current for a unit voltage, is determined.

Latest Insights & Trends from the Market

The recent news and data suggest that the global conductivity meter market will get a CAGR of approximately 6.7% from 2023 to 2030. This growth is fueled by increased demand across sectors such as water treatment, chemical manufacturing, food and beverage, and pharmaceuticals. The need for accurate water quality control, especially against the backdrop of environmental laws, has provided impetus to the enhanced conductivity measurement technologies.

The Asia Pacific market is predominantly huge, being stimulated by the fast industrial evolution and enhanced investments in clean water solutions in China, India, Japan, and so forth. From the technological perspective, the IoT-enabled conductivity meters stand out thanks to the real-time monitoring and analytics capabilities given to the operators to enforce operational margins and maintain quality parameters.

Key Applications and Advantages

Measuring the conductivity finds various applications, including monitoring water purity in industrial processes, ensuring correct mixing of chemicals, and testing product quality in food and beverage industries. Because of their accuracy and quick response time in measurements, conductivity meters are indispensible in keeping various industries safe and efficient. Also, with recent innovations such as touch-screen displays and wireless connectivity, the user experience has been improved considering even more convenience in both field and laboratory applications.

How Conductivity Sensors Function

The principle of conductivity sensors lies in the ability to measure current flow in a solution. Two or more electrodes may be used to generate a voltage across the fluid and detect the current flow in response. This current is directly proportional to the quantity of ions in the solution, and thereby it is used to measure the conductivity of the solution.

Measuring Electrical Conductivity in Liquids

Some parameters affecting the electrical conductivity of the liquid include temperature, ion concentration, and the type of dissolved ions. Temperature plays an essential part, increasing in conductivity with rise in temperature in most solutions. At higher temperatures, an increase in the mobility of the ions is observed; hence, conductivity increases. To compensate for such effects, conductivity sensors include temperature compensation algorithms.

Ion concentration represents the critical thing-the higher the dissolved ion concentration, the greater the conductivity. Seawater, with its salinity, is therefore given an average conductivity of 53,000 μS/cm, while freshwater rivers may range anywhere between 50 and 1,500 μS/cm depending on the environment. In addition, the kind of ions matters; ions such as sodium (Na+), chloride (Cl-), and magnesium (Mg2+) usually give a greater contribution to conductivity than do the larger, less mobile ions.

Conductivity sensors today use more sophisticated technologies, which include inductive or toroidal sensing for enhanced accuracy and less propensity for fouling in difficult industrial or natural environments. Such technologies allow conductivity to be widely measured for monitoring water quality, chemical production, and wastewater treatment to optimize processes and ensure environmental compliance.

Factors Affecting Conductivity Measurements

The list of interfering factors influencing the accuracy and reliability of conductivity measurements includes temperature, ion concentration, and sample composition. If application horizons and uses of conductivity data teaching due to the interpretation of conductivity data depend on these factors, then it is imperative to understand them.

Temperature

Temperature influences conductivity because it modifies ion mobility. Conductivity normally increases with temperature by approximately 2% for every 1°C rise. Keeping this in mind, conductivity sensors have ATC built in, whereupon to compensate the measured values to a reference temperature, commonly 25°C. Industrial water treatments are examples of specific sampling operations where samples must be maintained at uniform temperatures to reduce measurement uncertainties.

Ion Concentration and Composition

The solution's conductivity depends on the number and the type of ions present. Highly dissociated salts, acids, or bases increase the ion concentration and accordingly raise conductivity. For instance, seawater having a high concentration of dissolved salts generally has an average conductivity of about 50 mS/cm, whereas pure distilled water accounts for less than 1 µS/cm because very few ions are present. Measuring those differences could be of paramount importance, notably in desalination plants and environmental studies.

Presence of Contaminants

Contaminants such as organic matter, oil, or suspended solids are capable of fouling the sensors or affecting the ion activity while performing the conductivity measurements. Advanced types of technology, such as fouling-resistant inductive conductivity sensors, are applied to reduce such disruptions, primarily in wastewater treatment or industrial processes in which complex mixtures are involved. Thus, chemical production undergoes the application of anti-fouling sensors that remain accurate even in highly contaminated environments.

Real-Time Data Monitoring

A new technology helped to create the possibility of integration of real-time conductivity monitoring platforms with cloud-based systems, thereby allowing remote access and automated alerts. Since the introduction of smart sensors and IoT connectivity, continuous monitoring of water quality parameters in municipal water supplies is possible to ensure that the waters comply with safety standards such as those set by the EPA.

Proper accounting of these makes for reliable conductivity data in all sorts of applications, from environmental conservation to industrial process optimization. Looking to the future, advances in sensor technologies will assure even further improvement in the precision and adaptability of these conductivity measurement systems themselves.

Benefits of Using Conductivity Sensors

Conductivity sensors provide accurate and real-time measurements in almost every application, monitoring water quality, assuring process efficiency, and preserving system performance.

Accuracy and Reliability in Measurement

Conductivity sensors, by means of measurement, provide an accurate and reliable measurement in monitoring applications. Most modern sensors must meet digital features built in with an accuracy rating of ±1%, based on reading, model, and application. For example, operations where ultrapure water is used, such as semiconductor manufacturing and pharmaceutical sectors, require conductivity measurements in the range of very low microsiemens per centimeters (µS/cm) and even nanosiemens per centimeters (nS/cm); hence, with high-priority accuracy.

Temperature compensation and automatic calibration enhance the accuracy of conductivity measurements. This ensures that conductivity values stay at par even as environmental conditions change. Locally, wastewater treatment plants depend on such accuracy in real-time conductivity monitoring to calculate salinity adjustments in meeting regulations.

According to data from recent studies, operators are increasingly relying on conductivity sensors, with the global conductivity sensor market expected to grow at a compound annual growth rate (CAGR) of approximately 7% during the forecast period, 2023-2030. This growth finds its origin in the increasing demand for various applications in agriculture for soil salinity monitoring and power generation for boiler water analysis.

Conductivity sensors, being instruments of great precision, are still the reliable factor standards in exacting industrial and environmental processes.

Real-Time Monitoring Advantages

When conducting real-time monitoring, conductivity sensors offer advantages pertinent to industries at large. These sensors provide on-the-spot accurate data that build operational efficiencies by fostering informed decisions. As recent data suggests, the global conductivity sensor market is claimed to reach above $1.5 billion by 2030 owing to their heavy adoption in water treatment, chemical manufacturing, and food processing industries.

By way of example-working with water treatment and real-time data helps ensure optimum water quality by instantly detecting the level of salinity or contamination. Conversely, conductivity sensors in the food and beverage industries monitor cleaning processes on production lines to ensure that hygiene standards are rigorously applied. The growing trend toward linking conductivity sensors to IoT and smart systems is only further enhancing their potential to smoothly accommodate remote monitoring and enable predictive maintenance in complex industrial settings. Now, this technological synergy has made conductivity sensors vital instruments in the newer industrial and environmental workflows.

Key Features of Conductivity Transmitters

To me, conductivity transmitters have certain hallmark traits that are: precision, robustness, and versatility. These transmitters provide accurate measurements, supported by high-end calibration options, compatibility with many sensors, and simple interfaces that ease operation, thereby increasing productivity.

Range of Measurement and the Accuracy Let Us Consider

Today, conductivity transmitters are designed to accommodate a very broad measurement range, from 0.01 µS/cm on the low end to 2000 mS/cm on the high end, for applications extending from ultrapure water monitoring to industrial processes and wastewater treatment. Accuracy is another major consideration, sometimes to the point of being ±0.5% of the value detected. The most advanced types even come with temperature compensation algorithms to ensure accurate readings in varying environmental conditions.

The meter often comes equipped with multi-range selection, automatic calibration, and self-diagnostic features thereby enhancing operational efficiency. For example, in various fields such as chemical or food and beverage production, conducting real-time measurements is a must to control the quality. Most high-end conductivity transmitters are nowadays equipped with digital communication protocols of Modbus or HART, so that they can be properly integrated with the automated systems and the data is exact enough for refined process control.

Compatibility with Various Probes

Modern-day conductance transmitters are designed to support a broad category of measuring probes so that they may fit all possible industrial applications. These probes allow measurements of conductivity over various ranges from a solution with a highly concentrated acid to ultra-pure water. For example, the higher-end models are capable of handling conductivities as low as 0.01 µS/cm for use in the semiconductor industry and as high as 2,000 mS/cm for chemical processes.

Besides changes in design and features of transmitters, great improvements have been brought about in the sensors themselves. These sensors may now be coated with or made from new materials, such as titanium or PTFE, that make them resistant to corrosion and increase their durability in harsh environments. With the advent of smart sensing technologies, the transmitters can now achieve auto-calibration as well as auto-diagnostics, thus enhancing productive time while ensuring accuracy is not compromised.

Advanced systems, including Industrial Internet of Things (IIoT), use real-time data analysis and connectivity to improve the efficiency of conductivity transmitters. Recent industrial reports emphasize that machine learning algorithms can be integrated with these devices for predictive maintenance and operational optimization, which results in cost savings projected to reach $3 billion by 2030 in the industrial process sensor market.

Due to their integration capability, these advanced technologies transform conductivity transmitters into essential instruments for industries where precision, reliability, and data incorporation come first.

Guidelines for Choosing the Right Conductivity Sensor

When selecting the right conductivity sensor, I look out for things like measurement range, compatibility with my application, and environmental operating conditions. I also check to see if the sensor is durable, and accurate, or can interface with the systems I use, ensuring that it is best suitable to my needs.

Factors to Consider for Your Application

Measurement Range and Accuracy

Ensure the sensor covers the expected range of conductivity given your application. For practical industrial applications, conductivity ranges can vary widely-for example, ultrapure water may have conductivity as low as 0.055 uS/cm, to seawater at about 50,000 uS/cm. Whatever range you target, it is important to pick a sensor that offers highly precise readings relevant to performance. Modern sensors typically have a precision of about ±1-2% of the measured value, which is very important for industries requiring high-grade precision.

Durability and Material Compatibility

Conductivity sensors of special types and materials are required for various applications depending on the environment. For instance, the harsh chemical environment would require the sensors to be made of corrosion-resistant materials like stainless steel or titanium. Furthermore, sensors for high-temperature applications might sometimes be specified for service conditions of more than 212°F (100°C), thus allowing industrial use in processes like steam sterilization.

Integration and Communication Features

With the advent of the digital age, newer sensors have been equipped with digital communication interfaces, enabling their integration with PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems. Many sensors go as far as supporting communication protocols like Modbus, HART, or Ethernet/IP to facilitate a smoother flow of information. Research indicates that industries using sensors with digital communication gain up to 30% more efficiency in their processes due to real-time monitoring and automation.

Calibration and Maintenance Needs

Calibrating on a regular basis makes sure the sensor is giving an accurate reading throughout its lifespan. Most of the conductivity sensors nowadays allow automatic and single-point calibration systems. This means that the operator does not always have to intervene. Some industries save up to around 25% in maintenance labor by installing sensors with these features.

By performing a careful analysis of these factors and selecting the sensor best matched to your application needs, measurement reliability can be enhanced to ensure smooth operation on whatever application is in view.

Importance of Proper Calibration

Calibration holds the very essence for the right measurement of conductivity sensors, and we see a step-by-step procedure implemented in different industries like water treatment, pharmaceuticals, and food production. Industry reports and recent insights stated that such sensors with lack of calibration can result in 20% data inaccuracy, causing their production to be inefficient from time to time, pay more, or even go against regulations. Clean water treatment requires conductivity measurement of dissolved solids to ascertain whether the water is up to regulatory standards or not.

The new improvements disclosed in recent industry reports affirm that digital calibration tools and cloud-enabled sensors have been accounting for the up to 15% increase in calibration precision since the analog era. Besides that, automated calibration reduces downtime, which leads to enhanced productivity at the facility level while reducing errors made by human understanding. Analysts predict that such technologies may save businesses millions of dollars while reducing risk from untrue readings and raising operational performance.

An intermittent regularized automated calibration practice is one integrated with new technologies that ensure sensors are always reliable and provide accurate data, thus supporting the consistent production of quality results.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More