How Many Types of Flow Sensors Are There? Everything You Need to Know

Flow sensors are indeed vital parts of different sectors like manufacturing, automotive, healthcare, and aerospace. These instruments are the backbone of measuring and controlling the flow rate of fluids or gases, ensuring the systems operate at their best and attain maximum efficiency. However, the variety of flow sensors available in the market, each specifically designed for a particular application, makes the choice very difficult. This article aims at providing the reader with a thorough understanding of the different types of flow sensors, their operation, and where they work best. It does not matter if you are an engineer, technician, or a person working in the industry, the information provided in this guide will surely help you in making the right choice with regard to flow sensor selection and application.

What Are Flow Sensors?

Flow sensors measure the amount of fluid, either gas or liquid, flowing through a system or determine the flow rate. By providing up-to-the-minute data on flow conditions, these devices not only optimize operations but also keep systems safe. Real-time flow monitoring is indispensable in sectors such as water management, manufacturing, and energy systems, where the control of fluid dynamics must be precise for proper functioning and regulation.

Definition and Basic Functionality

Flow sensors have different branches according to their constructs and measurement methods, each better suited for its application. Among the commonly found types are differential pressure flow sensors, turbine flow meters, electromagnetic flow meters, ultrasonic flow meters, and mass flow meters. A case in point is differential pressure flow sensors that are preferred widely in industrial pipelines due to good performance, long life, and low price compared to other flow measurement methods. A market research report published in 2023 estimates that differential pressure flow sensors make up slightly over 35% of the total flow sensors market. This confirms their frequent use in the oil and gas industry.

Conversely, magnetic flow meters work best for conductive liquids and are widely used in the water treatment and chemical processing industries, which are unthinkable without them. Clinically and commercially, the accuracy of the sensors can be as high as 0.2%, making fluorometry very precise. Ultrasonic flow meters that employ sound waves for measuring flow rates are the "non-invasive" types; hence they are favored in such applications where the fluid's flow in the system is not to be obstructed.

Key Specifications and Performance Metrics

Today's flow sensors provide features that are above standard and they are also the reason for the increasing need for precision and efficiency to be met. The performance measures listed below are amongst the most recognized ones:

Measurement Range: different kinds of flow sensors can sense extremely low flow speeds down to 0.01 m/s to higher speeds that can surpass 10 m/s.

Operating Temperature: Most advanced flow sensors work in a wide range of temperature. Some even endure temperatures from as low as -40°F to as high as 400°F (-40°C to 204°C) which is extremely important in both industrial and research applications.

Accuracy and Sensitivity: For such applications that are critical, high-precision flow sensors can deliver tolerances up to ±0.5%, thus error and system accuracy are respectively minimized and ensured.

Real-Time Data Transmission: The use of IoT devices that send real-time data to the main system for monitoring and analysis has become common in the majority of modern sensors.

Industry Trends and Future Outlook

The annual growth rate (CAGR) of the flow sensor market worldwide is anticipated to rise 6.7% from 2023 to 2030, mostly due to the progress made in automation and the uptick in usage in renewable energy systems. AI-based data analysis and sensor material innovation, such as graphene, will soon be paving the way for even better performance.

The trend brings to the surface the gradually rising need of extremely accurate, real-time flow measurement solutions not only to optimize industrial processes but also to contribute to making sustainability goals achievable across sectors.

Role in Measuring Fluid or Gas Flow

Significant improvements in flow measurement technologies have not only increased their accuracy but also made them suitable for applications in various industries. A recent analysis revealed that the adoption of Coriolis and ultrasonic flowmeters has rapidly increased, contributing significant portions to the market in 2023. It has become common for Coriolis flowmeters, recognized for their precision in measuring mass flow and density, to be more frequently applied in the oil and gas, pharmaceutical, and food sectors. On the other hand, ultrasonic flowmeters are being frequently used for non-invasive measurements in the water management and clean energy areas those are hydrogen and geothermal power generation, respectively.

The estimates indicate that the world's flowmeter market is expected to reach $12.3 billion by 2030, driven by the growing demand for smart infrastructures. Besides, the integration of Internet of Things (IoT) technology with flowmeters enables immediate data gathering, remote supervision, and preventive maintenance. For example, IoT-enabled devices can reduce their operational downtime by up to 25% by warning in advance of any changes in flow conditions that might lead to equipment failure.

The geographical aspects also show that the Asia-Pacific area is leading in the acquisition of these technologies, driven by rapid industrial growth and government-supported sustainability projects. This trend underlines the role played by advanced flowmeters in the global market for efficient resource management and regulatory compliance.

Detailed Overview of Common Types

Advanced flowmeters are certainly going to be a major necessity in the fight against wastage of resources and the maintenance of the regulatory standards, particularly in fast-growing regions like Asia-Pacific. In my opinion, their ability to offer accurate measurements and live data is the most important factor that will enable the realization of both sustainability and operational reliability.

Turbine Flow Sensors: Features and Advantages

Turbine flow sensors function by means of a rotor that is positioned in the flow of the liquid, and this rotor rotates correspondingly to the fluid speed. Electrical signals are then obtained from this mechanical motion which results in providing very accurate measurements of the flow rate. As per the latest statistics, the accuracy of new turbine flow meters ranges from ±0.5% of the reading which makes them the best choice for applications that need such high precision. Enhancing these features is their cost-effectiveness and ability to handle liquids of both low and high viscosity with minimal pressure loss.

The latest breakthroughs in turbine flow sensor technology revolve around their cooperation with smart monitoring systems. For example, modern devices do not only have wireless communication but also advanced error detection features that make maintenance easier and faster. Reports from the industry say that the global turbine flow meter market is expected to increase by a CAGR of 6.4% through 2028 mainly due to the growing use of the product in the oil and gas, water management, and chemical processing sectors. Along with their rugged design and the ability to operate at high temperatures and pressures, turbine flow sensors are a key factor in improving productivity and efficiency in different sectors.

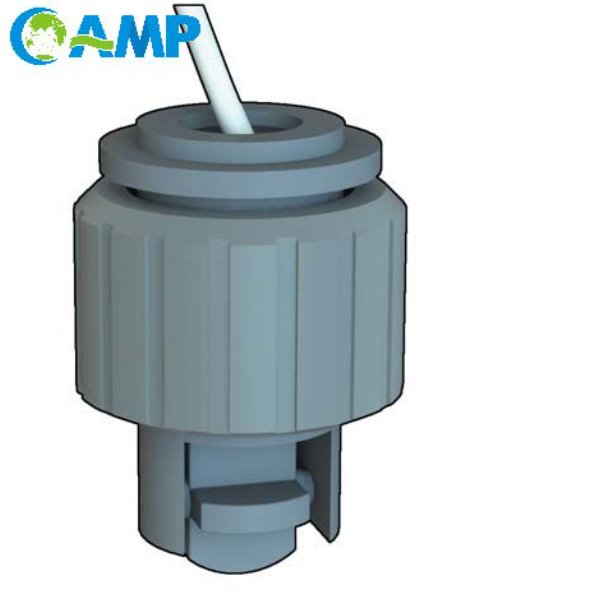

Thermal Flow Sensors: Ideal for Low-flow Applications

Thermal flow sensors are the ones that rely on the heat transfer principle which can be determined by measuring the cooling effect of the fluid that is passing through or over a heated element. These instruments possess high sensitivity and precision which makes them the best choice in low-flow applications. For example, even the most minute flow rates, as low as 0.1 milliliters per second, are detectable in some cases. The latest global industry report predicts that by the year 2025, the global thermal flow meter market would reach $3.2 billion, the $3.2 billion market growing at a CAGR of about 5.3% during the period. This market growth is mainly driven by the increasing application of accurate low-flow measurement in industries like pharmaceuticals, life sciences, and microfluidics.

Among the factors that keep thermal flow sensor technology on the cutting edge is the incorporation of MEMS (Micro-Electro-Mechanical Systems) technology in thermal flow meters. This technology allows compact designs and at the same time gives accurate readings even in the most difficult environmental conditions. Moreover, the utilization of thermal flow meters in the coming time is expected to surge due to their advantages over the traditional sensors regarding low-pressure drops, reliability when it comes to measuring flowing gas-based fluids, and easy maintenance.

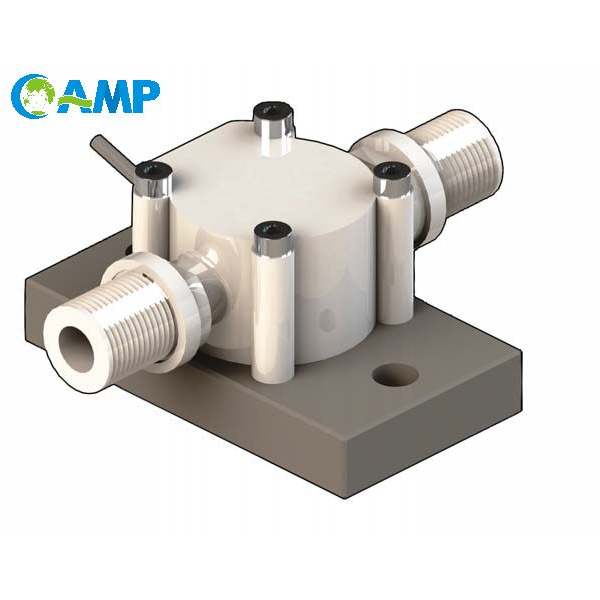

Electromagnetic Flow Sensors: Best for Conductive Fluids

Electromagnetic flow sensors are not only intended for electrical conductivity measurement but also play a vital role in water treatment, chemical processing, and food and drink manufacturing therefore being a necessity in the mentioned industries. Their operation is based on Faraday's Law of Electromagnetic Induction stating that electric voltage will be generated and will be proportional to the flow velocity when a conductive liquid passes through a magnetic field. The output voltage is thus measured and then converted into a flow rate.

The modern electromagnetic flow sensors are equipped with sophisticated signal processing that guarantees precision even for fluids with widely varying conductivities. A research effort has proven that the measurement value of these sensors might even reach ±0.2% accuracy limits, and some models can handle flow rates ranging from below 0.2 ft/s to over 39 ft/s. A characteristic aspect of their non-intrusive design is that there are no moving parts involved which, in effect, allows for declining repair and maintenance needs.

They have found one of the most significant applications in the area of water management systems: monitoring municipal water supply networks. To illustrate, a study conducted in 2023 has disclosed that electromagnetic flow meters played a role in improving the detection of leaks in urban water grids by 15%, resulting in significantly reduced costs and increased water savings. In addition, they maintain a high-performance level even in extremely hot and corrosive fluids; therefore, they are used in a wide range of industrial processes, from the chemical to the food and beverage industries.

While the future of electromagnetic flow sensors is characterized by the implementation of such advanced technologies as cloud connectivity and improved diagnostics, they are evolving towards being used in predictive maintenance which in turn leads to less downtime, increased reliability, and overall system efficiency, thus their role in critical flow measurement applications will be further reinforced.

Applications of Different Flow Sensor Types

I would classify the uses of different flow sensor types depending on their specific characteristics. Turbine flow sensors are the most suitable for applications requiring high precision and flow rate measurement, such as certain industrial and water distribution systems. On the other hand, thermal flow sensors perform best in low-flow situations and are therefore most in demand for gas flow monitoring in research or HVAC areas. Electromagnetic flow sensors make it possible to deal with conductive fluids, which can be found in wastewater treatment and the chemical processing industry. The app's requirements can match the sensor type chosen, ensuring quality performance and precision in measurement.

Applications: Oil & Gas, Chemical Processing, and Manufacturing

Flow sensor technology has made various strides aimed at enhancing measurement accuracy, operational reliability, and the ease of linking flow sensors to modern industrial systems. For example, the global market for flow sensors is expected to increase at a rate of 6.1% a year from 2021 to 2028, primarily due to the rising need for this product in the sectors of oil and gas, chemical processing, and water treatment.

The use of IoT (Internet of Things) capabilities in the flow sensors is a significant achievement, as it provides opportunities for real-time data gathering and monitoring from remote locations. The IoT-enabled flow meters are especially useful in maintenance strategies that rely on observing potential defects. They help factories keep production running by preventing machine failures through early detection. Furthermore, continuous development in microelectromechanical systems (MEMS) has also led to the manufacturing of extremely tiny flow sensors with very good performance. These latest innovations are the main factors in the applications that require the utmost precision like making pharmaceuticals and the production of semiconductor devices.

Changing the materials around the sensor is another impactful area in the flow sensor industry, resulting in sensors that are more durable and better. In such cases, the application of coatings and usage of materials like Hastelloy and PFA (Perfluoroalkoxy alkane), which are resistant to corrosion, are some of the common practices that are done in order to secure the sensor's life even in aggressive conditions, such as working areas with strong acids or extremely high temperatures. Also, using enhanced digital signal processing methods has bolstered the noise immunity of flow sensors, so even in the most difficult operational conditions one can still get trustworthy data from the sensors.

These technology advancements highlight the necessity for the industrial operators to constantly check and perhaps even reassess the flow sensor's specific performance factors of long-term accuracy, response time, and compatibility with advanced process control systems so that they can remain competitive.

Medical Applications: Respiratory Devices and Fluid Monitoring

A major application of flow sensors in the medical field is in respiratory devices and fluid monitoring systems. Modern respiratory equipment, such as ventilators, now uses flow measurement to adjust oxygen delivery to the patient according to their breathing patterns, thanks to the progressive development of sensor technology. The flow sensors are units made to measure bidirectional flow and the very best in sensitivity and speed among other characteristics. Real-time patient care is needed as an example; thermistor-based flow sensors and differential pressure sensors are commonly utilized due to their accuracy and dependability.

Moreover, in fluid monitoring systems, flow sensors are incorporated; for example, in intravenous (IV) drug delivery devices, precision is crucial to ensure the correct dosage and flow rate. Studies done recently show that advanced flow sensors can claim the accuracy of ±0.5% of the measured value for low flow rates and this is significant in improving the patients' welfare in the critical care area.

As per the current data, the global medical flow sensors market is expected to see a growth rate of 6.8% CAGR from 2023 to 2030. This market trend is a result of the increased production of home-based healthcare devices and the widespread application of sensor-integrated technologies in hospitals, besides other factors. Likewise, manufacturers are working on making their products smaller, which, in turn, leads to more compact designs. The latter, of course, can easily fit into a portable medical device without taking away from quality and reliability. Such innovations indicate that the healthcare and technology worlds are converging in the areas of patient safety and improving medical treatment efficacy.

Environmental Monitoring: Water Treatment and Air Quality

Environmental monitoring has been a necessary process to prevent health issues to the population as well as to make sure the regulators are getting what they want. The high-tech sensors are now the main players in monitoring vital factors in water treatment and air quality management processes. A report published by MarketsandMarkets in 2023 states that the global environmental monitoring market will almost double in size, rising from $14.5 billion in 2021 to $21.8 billion in 2026. This indicates a growth at a CAGR of 8.6%. Thus, the demand for advanced and trustworthy solutions to counteract pollution and environmental deterioration is growing stronger.

Water Treatment Monitoring

Water treatment is the process that makes water suitable for human consumption. Depending on the water quality, different treatments might be applied, i.e., chlorination, ozonation, UV radiation, etc. But no matter what kind of combinations of treatments are used, they always rely on the real-time capability of the technology to monitor such parameters as turbidity, pH levels, chemical oxygen demand (COD), and total dissolved solids (TDS). For example, real-time monitoring systems utilizing IoT connectivity have been widely adopted to detect contaminants and optimize treatment processes. Data-driven insights from these advanced platforms have been instrumental in reducing operational costs while improving water quality compliance rates. Notably, the U. S. Environmental Protection Agency (EPA) mandates specific water quality standards, and these innovations help ensure adherence to such stringent regulations.

Air Quality Monitoring

Technologies are applied in the area of air quality monitoring to keep track of particulate matter (PM2.5 and PM10), carbon dioxide (CO2), nitrogen dioxide (NO2), and volatile organic compounds (VOCs), which are the most critical pollutants. The portable and fixed air quality monitors equipped with optical or laser-based sensors are now installed and are able to give non-stop and accurate data. One of the World Health Organization (WHO) reports asserts that air pollution accounts for around 7 million premature deaths globally every year, highlighting the need for prompt and reliable monitoring systems. To avert health dangers in cities and factories, the partnership between sensor technology and machine learning models is already so advanced that it has begun to offer prediction and mitigation strategies.

The environmental monitoring systems' integration with the cloud-based platforms not only provides a possibility to the environment monitoring to keep track of all types of pollutants in real-time but also helps with reporting. The tools have aligned with global efforts to reduce pollution, enhance environmental sustainability, and proactively address public health and safety challenges.

How to Choose the Right Flow Sensor

The features of the fluid or gas being measured are the main consideration when I choose a flow sensor, and I make sure to include conductivity, viscosity, and temperature among the criteria. The environmental conditions are evaluated, e.g. pressure that the sensor will be under and possible exposure to corrosive elements. Then, I bring my selection into close alignment with the application's accuracy, response time, and compatibility needs. At the end of the process, I assure you that the sensor is in conformity with industry standards and does not pose any operational difficulties.

Factors to Consider: Fluid Type and Properties

One of the most important factors in selecting a flow sensor is the type and properties of the fluid, including environmental conditions such as operating pressure, temperature, and potential exposure to contaminants or corrosive elements. The most current industry trends indicate that high-pressure applications will usually require specific flow sensors. These sensors are designed to withstand the pressure and have very strong housings made of materials like stainless steel, providing high durability and resistance to deformation. For chemicals that are corrosive or aggressive, the use of PTFE (Polytetrafluoroethylene) or Hastelloy is very common because of their outstanding chemical resistance.

Moreover, studies have shown that the sensor in extreme temperature should be provided with temperature compensation capabilities for proper accuracy. For example, thermal mass flow sensors frequently incorporate advanced compensation algorithms that improve their performance under varying thermal conditions. The data from the manufacturers suggests that many industrial-grade flow sensors have an operational temperature range of -40°F to 300°F (-40°C to 150°C), thus offering reliability across various applications. The sensor's material and design should be compatible with both fluid properties and environmental conditions in order to achieve maximum performance and longevity.

Operating Environment Considerations

The selection of the right materials for flow sensors is a key factor to the durability and operational efficiency in particularly corrosive or chemically aggressive environments. The most recent industry statistics show that stainless steel is still the most preferred metal for many industrial processes due to its excellent anti-corrosive properties, strength, and ability to work under extreme temperatures. For very corrosive liquids the application of advanced materials like Hastelloy, titanium, or PTFE coatings are quite common. For instance, PTFE (Polytetrafluoroethylene) has the capability of withstanding temperatures up to 500°F (260°C) and it is completely inert, thus, making it very suitable for applications that involve aggressive acids or solvents.

says that almost 70% of the flow sensor system failures happen due to the degradation of the materials because they are used in environments that are not compatible with them. To prevent this situation, the manufacturers suggest the use of a predictive maintenance strategy along with the thorough pre-operation analysis of the fluid properties, including pH level, particulate concentration, and viscosity. This method will make sure that the materials have the required strength against the chemical wear and operational stress thus will maximize the lifespan and reliability of the sensors at the same time.

Innovations in Flow Sensor Technology

I suggest that a full set of pre-operation fluid analyses should be carried out in order to evaluate variables such as pH, particulate concentration, and viscosity. Predictive maintenance techniques will also be very useful in keeping the sensor materials impervious to degradation which will in turn improve the sensor's life and use in the tough environments.

Emerging Trends: IoT Integration

The merging of the Internet of Things (IoT) technology into flow meter systems has led to great progress in data gathering, remote observation, and predictive analytics. Present day IoT flow sensors are not just measuring liquid flow rates with a high degree of accuracy but also sending the data instantly to a central control unit through wireless networks. A current report from Markets and Markets says that the Internet of Things (IoT) sensors market will expand from a value of $10.9 billion in 2023 to a value of $29.4 billion in 2028 which represents a compound annual growth rate (CAGR) of 21.2%. The major factor driving this upsurge is the increased implementation of IoT gadgets in sectors like water management, oil and gas, chemical processing, and manufacturing.

IoT-enhanced flow meters offer cutting-edge features such as remote diagnostics, automated calibration, and machine learning to detect fluid flow irregularities. To illustrate, in the case of water utilities, IoT sensors allow constant monitoring of both the flow rates and pressure levels, which in turn helps to reduce leakage, and by such actions, water is optimally distributed. Furthermore, in case of such sensors, there is also frequently the provision of measuring multiples parameters which not only provides the information about flow rates but also the temperature, pressure, and density. This facility is indispensable in areas such as a petrochemical plant where unplanned shutdown can cost up to millions of dollars every hour.

Flow data recorded by IoT flow meters is usually analyzed through cloud computing platforms that use cutting-edge analytics resulting in predictive maintenance and operational effectiveness. These platforms can, through the evaluation of historic flow trends and continuous inputs, foresee likely failures and suggest corrective actions that would lower the maintenance expenses by as much as 30% according to some industrial research. The mixing of IoT technology with flow sensors so smoothly is expected to bring about a complete change in the functioning of industrial systems turning them into smarter, more dependable, and energy-efficient ones.

Miniaturization and Energy Efficiency

The latest breakthroughs in miniaturization and energy efficiency have been the driving force behind the sensor technology developments in industrial applications. The modern flow sensors are designed to be smaller and lighter while maintaining the same functionality and accuracy. Current studies state that the global demand for miniaturized sensors is expected to rise from US$303.2 million in 2023 to US$641.0 million in 2030 at a CAGR of 10.8%, mainly due to increasing applications in industries such as manufacturing, healthcare, and IoT-based smart systems.

Another important aspect is that of energy efficiency and it is going to be the main area of development. Besides that, new innovations in low-power circuitry have sensors that operate continuously for extended periods while consuming very low energy. For example, the development of nanostructured materials and energy harvesting technologies makes it possible for flow sensors to use the power from their environment, e.g. vibrations or ambient light. Allied Market Research states that IoT systems powered by energy-efficient technologies can have up to 40% reduction in operational power consumption, which in turn means huge savings over time.

Moreover, manufacturers are coming up with new methods of fabrication such as 3D printing and MEMS (Micro-Electro-Mechanical Systems) technology that not only build on the scalability and precision of miniaturized sensors but also push their limits. These methods will result in lower production costs and, at the same time, make it possible to integrate the sensors in larger and more complicated areas, thus increasing their application range. The technological advances, in turn, will keep the demands of the industries, and flow sensors will continue to be the main contributors to the sustainable and optimized operations of the future.

Advanced Materials for Durability and Performance

The contemporary flow sensors are making increasing use of hi-tech materials in the fields of durability, performance, and accuracy of the measurement as well as in the lifetime of the operational continuous system. Silicon carbide (SiC) and ceramic composites materials are being used due to their excellent mechanical strength and wear and corrosion resistance. For instance, silicon carbide, which is often recognized for its thermal conductivity and chemical stability, is mainly used for extremely demanding environments like oil and gas production, where temperature and chemical media are aggressive.

In 2025, a study demonstrated that sensor devices made of ceramic-based materials were about 35% more durable than those made with traditional stainless steel. Also, to the advancement in surface coating technologies among which diamond-like carbon (DLC) coating offering a friction reduction of up to 50% could be mentioned, the sensors become more sensitive and responsive. Such innovations in materials are leading to the production of flow sensors that can endure tougher conditions while still offering high accuracy and reliability for extended periods.

Using such advanced materials in flow sensors also corresponds to the sustainability target, as increased durability means a lower rate of replacement thus leading to less waste of materials and costs in the long run. The progress in technology signifies the continuous endeavor to refine sensor technology for the most demanding applications across various sectors.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More