What is a Flow Sensor? Exploring Its Role and Applications

Measuring the liquid, gas, or other medium in accurate volumes is a part of the activities of hundreds of industries, such as production, automotive systems, healthcare, and environmental ethics. In all these activities, a flow sensor is an instrument used to ensure operational efficiency, accuracy, and safety control of the linear movement of substances. This section briefly answers the question of what is a flow sensor, how it works, and its range of variabilities that have proved to be useful in the discussed fields. Understanding the modes of operation and importance of such devices in the aforementioned broader context enables appreciation of their indispensability in the current era of technological and industrial progress.

Introduction to Flow Sensors

Ever wondered how the flow of gas or liquids can be measured? To answer that, there is what is called a ‘flow sensor’. These sensors, which are installed in ducts, monitor a change in medium properties such as the pressure, the temperature, and the velocity. The data from the flow sensors has several applications in self-regulating industrial practices and certain medical devices, where the control of the flow of fluids or gases is critical. Flow sensors help in improving efficiency, reliability and performance of various systems.

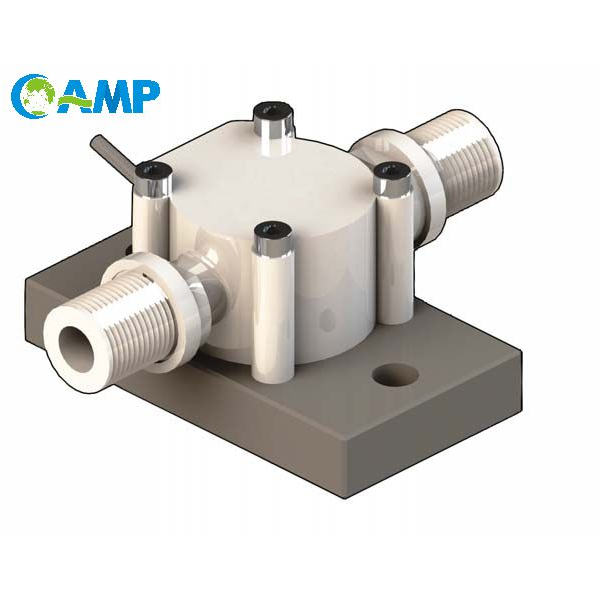

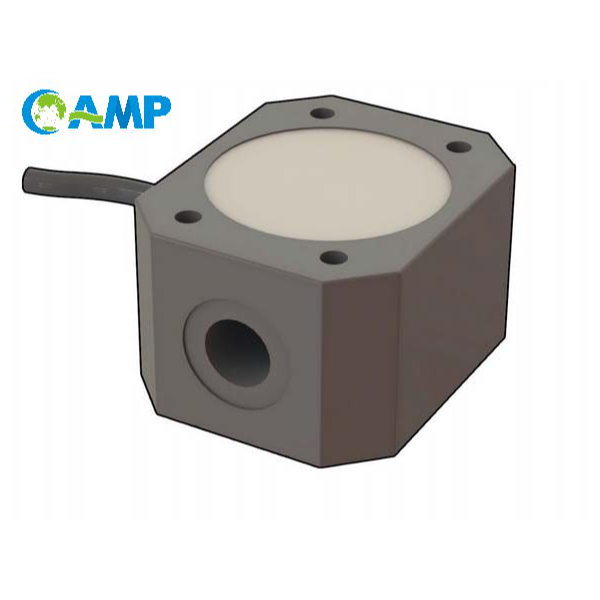

What is a flow sensor?

In the field of sensor technology, a flow sensor is traditionally classified according to the technique it employs to detect the flow of gases or liquids. The basic types include pressure drop sensors, ultrasonic sensors, thermal flow sensors, paddles, and whirl cones. It is essential to note that all types suit certain environments and industry expectations, reaching different levels of precision and responsiveness, as well as the most appropriate usage.

Flow Measuring by Pressure Drop: It is the most common type of flow measurement device, which uses an orifice, venturi, or nozzle with pressure differential technology. They are typically found in many industries, especially oil and gas, where precision measurement is the key. It has been noticed that these sensors represent about 26% of the market segment of flow sensors worldwide as per the latest industry dynamics.

Ultrasonic Flow Sensors: Sonar waves are used in this type of sensor to measure flow, allowing it to be highly accurate and non-invasive when in use. These are especially useful in fields such as water treatment and chemical industries, where its vital to measure flow without physical contact. Today’s technologies can determine the flow of fluids even if they are mixed or not homogenous.

Thermal Mass Flow Sensors: These sensors are excellent for low rate flows because they sense the heat lost by the fluid or gas that passes through. In HVAC industries and laboratories, they are particularly helpful in precision-oriented tasks.

Turbine Flow Meters: The rotational movement is produced, and these meter directly measures the volumetric flow rate. High reliability makes them widely used for measuring fuel supply. The only cons are that these meters are not suitable for dealing with fluids with high viscosity and suspended solids.

Vortex Flow Meters: Based on vortex shedding technology, these are suitable for gas and steam flow measurement. These vortex flow meters is widely known to be rugged that can withstand the abuse they may expose in a rugged industrial atmosphere.

Accuracy and Technologies

Recent designs of flow meters have empowered technologies like microelectromechanical systems (MEMS) to utilize materials that enhance miniaturization and ensure high precision and efficiency. The year 2025 market data shows a formative trend towards IoT flow sensors which are utterly integrated in smart systems for monitoring and maintenance purposes. Thus, it strengthens operational performance and, in the context of energy conservation, selectively decreases resource expenditures.

Flow sensors find themselves in a range of applications, with their use seen in aerospace, pharmaceuticals, and renewables, among many other sectors, and as such, their demand is forecasted to increase at a rate of between 6 and 8 percent on a CAGR basis to impractical extent, by the end of 2030 as various industries continue investing in data intelligence and sustainability.

Significance in Various Industries

Any industrial process involving fluid transfer and requiring efficiency and accuracy depends upon these flow sensors. There are probably thousands of uses for a flow sensor; just one commonality, though, is the need for measurement to be done on-the-go in less time and used for controlling systems. For example, in the pharmaceutical arena, sophisticated flow sensors are used to measure liquid and gas quantities with high precision during production so as to adhere to stringent standards while reducing wastage of raw materials. In the renewable energy industry, they are vital in optimizing fluid transfer systems within solar-thermal plants and hydro operations, thereby supporting the transition to green-energy options.

Reportedly according to market research, the flow meter market worldwide was valued at nearly USD 7 billion in 2022 and is forecasted to reach USD 12 billion by 2030, growing at a CAGR of 6-8%. North America and Asia-Pacific are leading the way as their industrial bases grow and demand for smart technologies increases. Meanwhile, IoT and Industry 4.0 advancements have enhanced the demand for smart flow meters capable of wireless communication and predictive maintenance. With this technology, operators can reduce downtime, increase safety, and promote the sustainable operation of plants.

Since then, from enhancing industrial efficiency to supporting intelligent and interconnected systems across various sectors, flow sensors will continue to play a pivotal role.

Common Terminology: Flow Meter

Thanks to recent developments in flow meters, the scope for accuracy, efficiency, and adaptability has increased exponentially over time. The present-day data state that the global flow meter market is projected to witness an impressive CAGR of nearly 6.8% from 2023 to 2030, achieving a valuation closer to $13.8 billion by 2030. Increasing automation in several industries, including oil and gas, water and waste management, and chemical processes, is driving growth.

One key innovation is the adoption of ultrasonic and electromagnetic flow meters that provide high precision without requiring complex mechanical components. These technologies use advanced algorithms to analyze flow patterns, reducing the margin of error to ±0.2%. To add to digital connectivity improvements, the integration with IoT platforms allows for real-time monitoring and data analysis. For instance, industries using wireless-enabled flow meters find maintenance costs reduced by the tune of 30%, thanks to predictive diagnostics that alleviate hardware failure before it dawns.

Moreover, sustainability trends have expedited the need for energy-efficient meters. For example, thermal mass flow meters have buoyed in energy conservation efforts in industrial processes to improve operational efficiency. These advances show how the technology of flow meters continues to evolve, keeping pace with industrial demands today.

How Flow Sensors Work

Flow sensors measure the rate of flow of some fluid or gas through a system. These mechanisms would generally operate through thermal dispersion, differing pressure, or electromagnetic induction to detect flow velocity and volume with high accuracy. Such technologies interface with electrical signals from the raw physical data of flow, thus making possible the precise real-time monitoring and analysis of the flow.

Measurement Principles: Volume, Mass, and Velocity

Flow measurements function on three principle forces--volume, mass, and velocity--each suited to specific applications in various industries. Volume flow rate is measured commonly in cubic meters per second (m³/sec) or liters per second (L/s) and indicates the amount of fluid that passes through a system during a given time. For instance, it finds applications in water distribution networks as well as industrial processes that require an accurate volume flow measurement to determine the overall performance of the systems involved.

The mass flow rate is defined as the quantity of fluid that passes a point in space over a unit of time (e.g., kilogram/second). Coriolis mass flow meters are able to measure the mass flow rate with great accuracy. They are thus used in chemical manufacturing processes where strict ratios are maintained in the materials. Recent developments in sensor technology enable a margin of error of ±0.1% in essential operations, thereby fulfilling the requirements of critical processes.

Velocity-based measurements give us clues about how the flow system behaves. Using either ultrasonic or electromagnetic sensors, the system determines flow velocity by calculating the speed of the medium passing through a given area. For instance, ultrasonic flow meters using the transit-time method may be accurate to ±1% in even large diameter pipes, where flow profiles might vary.

With a CAGR of 6.7%, the global flow sensor market is expected to grow from 2023 to 2030, according to industry reports from reliable sources. This upward projection is the result of increasing demand for accurate flow measurements in industries like oil and gas, pharmaceuticals, and water treatment plants. AI-based processors along with wireless communications help the instruments to carry out real-time diagnostics and predictive maintenance, and this ability enhances their importance in the frame of modern engineering systems.

Mechanical vs. Electrical Methods

The progressive advances in measuring flows reveal the transition from traditional methods to highly sophisticated systems driven by modern advancements. According to some recent reports, the global flow meter market size is expected to touch almost $13.3 billion by 2030, with driving factors including the increasing adoption of advanced instruments in varied industrial applications. Of these instruments, ultrasonic and Coriolis flow meters are seeing accelerated adoption due to their high accuracy, very low maintenance, and ability to measure both mass and volume flow rates.

In a report by market analysts, it has been stated that ultrasonic flow meters are gaining prominence in natural gas processing and water distribution operations. This is due to the necessity for exact and non-destructive measurements, given the growth of multi-path technology. Coriolis meters, on the other hand, having gained favorization in chemical and pharmaceutical industries for they can directly measure mass flow without consideration of fluid density or viscosity, are those that became extremely popular for those purposes.

Moreover, the integration of smart features and systems involving IoT-enabled communication and AI-assisted calibration is setting the new industry standards. Apart from real-time data logging, remote monitoring and predictive maintenance solutions are enhancing operational efficiency and cost savings by reducing downtime. Recent case studies within oil refineries recorded reductions in maintenance cost of up to 30 percent by using advanced flow metering systems for predictive diagnostics. This directly improves productivity while also potentially contributing toward industry sustainability goals through best usage of resources.

Continued innovation backing these technologies and the implementation of the new generation highlight the status as a backbone of industrial growth and operational precision for advanced flow measurement systems.

Applications of Flow Sensors

Flow sensors are installed in various places, such as industrial processing levels, HVAC works, water management, and medical devices. I find them invaluable in ensuring proper monitoring of fluid or gas flow alongside maximizing system performance in safety-critical operations.

Industrial Applications

Flow sensors have an extremely important role in industrial applications, especially in oil and gas, chemical processing, and manufacturing. A recent study shows that the global flow sensor market is projected to register a CAGR of 6.2% from 2023 to 2030, mainly triggered by increasing demand in process automation and IoT-enabled devices. These sensors are used for monitoring and controlling the flow of liquids, gases, or steam through industrial pipelines to ensure operational efficiency and compliance with tight safety regulations.

A compelling example would be oil refineries, where ultra-precise flow measurements are required in areas like distillation and cracking to maximize output and minimize wastage. Modern flow-sensing equipment uses advanced technologies, including ultrasonic and electromagnetic principles, and can generate output that is accurate to ±0.1% of the flow measured. Moreover, the real-time data generated from these installation functionalities promotes predictive maintenance and reduces downtime, further enhancing productivity in industrial setups.

The integration of advanced flow sensor systems with Industry 4.0 technologies has enabled remote monitoring capabilities, simplifying the management of complex operations in large-scale facilities. This shift attests to the indispensable role that flow sensors will play in automated and sustainable industrial practices ahead.

Medical Applications

Flow sensors help medical applications by ensuring accurate measurements and monitoring vital parameters in healthcare systems. There are flow sensors for respiratory instruments such as ventilators, CPAP (Continuous Positive Airway Pressure) systems, and anesthesia systems, where the airflow must be sufficient to preserve life. These new developments have enabled the production of highly sensitive flow sensors using microelectromechanical systems, providing better accuracy and miniaturization.

As of today, the world medical flows sensors market is expected to register a CAGR of about 6.8% from 2023 up to 2030. This growth is driven by an increasing demand for advanced respiratory care devices, especially after a pandemic that was testing the very fabrication of reliable ventilation systems. For instance, MEMS-based flow sensors are designed to measure both low and high flow rates with great accuracy, optimizing therapeutic delivery during mechanical ventilation situations.

Moreover, flow sensors in infusion pumps and dialysis machines measure liquids and gases accurately, allowing the performance of critical functions. These sensors help healthcare professionals to monitor treatment parameters and adjust treatments to improve results for the patients. With newer advances in the Internet of Medical Things (IoMT) devices, flow sensors are being integrated further into digital healthcare ecosystems, ushering in real-time data transmission and remote sensing that enhances operational efficiency and healthcare delivery.

Environmental Monitoring

Flow sensors find a huge application in monitoring environmental aspects as they help regulate and accurately measure water and air quality. Their uses include leakage detection in pipelines, monitoring flows in rivers and reservoirs, and managing industrial emissions. In view of recent statistics, the global flow sensor market is set for a CAGR of 5.8% between 2023 and 2030 as their application in environmental protection is gaining momentum.

For example, flow sensors in smart water management systems measure the flow rate and volume of water distributed in urban areas, thereby presenting up to 30% saving through early leak detection. In air quality management, precise flow sensors monitor particulate matter and gaseous pollutants so industries and governments can meet environmental regulatory standards. The application of IoT technology further extends the capability of these monitoring systems by collecting and analyzing data in real-time, thereby enabling predictive maintenance and swift response to environmental changes. The synergy between flow sensor technology and IoT analytics is proving to be critical in conserving natural resources and lessening the adverse effects of industrial activities on the environment.

Choosing the Right Flow Sensor

When choosing the flow sensor, I factor in the fluid or gas measured, the desired flow range, operating pressure, temperature conditions, and accuracy level. The compatibility of materials with the system and compliance with industry standards are paramount to long-term reliability and optimization of performance.

Accuracy and Precision

Accuracy and precision are interrelated in flow measurement, affecting data reliability and industrial system performance. Accuracy indicates how close one measurement is to some intended value while precision measures how consistent repeated measurements are. Recent technologically advanced flow sensors suggest magnetic flow meters to be best with an accuracy of ±0.2% of the measured value for conductive fluids, hence preferred mostly in water treatment and chemical industries.

Through the use of modern ultrasonic flow sensors, utilizing technologies such as the transit-time and Doppler ultrasonic flow methods, respectively, only the finest precision is achievable; flow rate readings hardly ever vary more than ±0.5 to ±1%. According to well-established calibration procedures traceable to organizational authorities such as NIST (National Institute of Standards and Technology), these instruments would yield a dependable data set for intricate cases where practical application calls for high-viscosity fluids at variable flow velocities. When installed, aligned, and maintained adequately, installation and in-service training further enhance accuracy and precision, thereby reducing residual inefficiency and incompatibility with regulatory statutes.

Fluid Compatibility and Operating Conditions

When selecting flow measurement instruments, it is crucial to consider the device's compatibility with the chemical properties of the fluid and its operating conditions. Anyhow, to state certain physical properties of fluids, factors such as viscosity, density, temperature, or corrosiveness can be detrimental to measurement accuracy or even damage the device. For example, very corrosive polymer chemicals, such as sulfuric acid, would require flow meters fabricated in special materials like Teflon or Hastelloy to prevent the material from degrading during use.

Also, the operational conditions, such as temperature and pressure ranges, have to accord with the instrument's design specifications. Today's flow meters are equipped with materials and sealing mechanisms that ensure they could weather adverse industrial environments. According to recent sources, ultrasonic flow meters afforded substantial accuracy (±0.5% of the reading in some cases) within broad temperature ranges and could also operate at pressures of up to 100 bar in a few configurations. They were also set to give good results for conductive fluids within the accuracy range of ±0.2% to ±1%.

Increasingly, the market for specialized instrument systems intended for extreme application environments is showing new potentials. For instance, global flow meter markets saw heavy demand for devices used in cryogenic; manufacturers report satisfying operation at temperatures as low as -200°C (liquid nitrogen or LNG). This further highlights the need for detailed fluid evaluation and instrument configurations to optimize the instrument's performance and ensure long-term reliability in any application scenario.

Durability and Maintenance Considerations

Recent developments in material engineering have greatly enhanced the performance and durability of instruments for extreme environments. Flow meters are usually constructed from high-grade stainless steels, titanium alloys, and advanced ceramics to provide resistance to corrosive fluids and maintain integrity under large pressure variations. A recent market analysis stated that the global flow meter market is expected to grow at a CAGR of 6.4% between 2023 and 2030, fueled by the adoption of advanced materials and technologies.

In addition, sensing equipment and internal components modified with coatings and surface treatments (e.g., DLC coatings) have their abrasion-wear resistance improved. This aspect has been crucial in industrial sectors storing highly acidic or alkali solutions—the prolonged incubation significantly damages the generally accepted components. According to operational data from leading manufacturers, these advanced solutions have enabled flow meters to achieve an average lifespan extension of 30% in the chemical and oil-and-gas industries, while also reducing maintenance costs.

Correct material and engineering design selection make an instrument reliable and maximize its efficiency under temperature fluctuations, high salinity, or volatile chemical exposures.

Innovations in Flow Sensor Technology

Briefly, I would consider the specific application requirements, such as the type of fluid or gas, flow range, and operating conditions. I would also ensure that the sensor is compatible with the system's materials, that it meets industry standards, and that it affords the desired level of accuracy. From there, I would prioritize durability, ease of maintenance, and any new developments that may have arisen in sensor technology-that is to say, anything that promotes reliable and efficient performance.

New Materials and Designs

Recent developments in sensor technology have witnessed the emergence of novel materials and designs that have greatly enhanced performance and reliability. Graphene-based materials, for instance, have led to sensors with improved sensitivity due to graphene's excellent electrical and mechanical properties. According to studies, graphene-based sensors can detect changes in gas concentrations at the molecular level, possessing detection limits as low as parts per billion.

Another emerging trend presents the use of microelectromechanical systems (MEMS) in sensor creation. The latest MEMS technology permits miniaturization and allows sensor integration, thereby making sensors smaller and more power-efficient without any compromise on accuracy. Modern MEMS sensors function well even in very hostile environments, with temperature ranges exceeding 300 °C in some cases.

As cited in recent industrial reports, the global sensor market is expected to grow at a CAGR of 8.5% from 2023 to 2030, driven by key demand from the automotive sector, healthcare, and manufacturing. For example, in automotive applications, piezoresistive pressure sensors are increasingly being adopted to enhance fuel efficiency and emissions monitoring.

These developments serve to highlight the rapidly evolving sensor technology, which demands further sophistication, longevity, and versatility across all sectors.

Integration with IoT Systems

Integration between pressure sensors and IoT systems brings about a drastic change in industrial operations and consumer applications by providing real-time data gathering and analysis. The recent reports predict the IoT market will reach $1.1 trillion by 2028, bringing with it enormous opportunities for the widespread implementation of sensor-based ecosystems. These sensors interact with IoT frameworks for condition monitoring, predictive maintenance, and automation in very stringent applications.

One exemplary industrial application includes pressure sensors in conjunction with IoT-based platforms that oversee HVAC units, pipelines, and reactors to maintain operational efficiency and take a proactive approach in troubleshooting. The data flows into cloud-based analytics platforms, so that stakeholders may track key performance metrics, in real time. For healthcare applications, pressure sensor-imbued wearables are being linked with IoT networks to deliver uninterrupted patient monitoring for ailments such as hypertension and sleep apnea, thereby improving patient outcomes with timely intervention.

Wireless communication protocols such as 5G further advance this amalgamation of pressure sensor technology with IoT by reducing latency while increasing the reliability of data transmission. These developments drive home the fact that the sensor-IoT integration is a catalyst of innovation and efficiency across industries.

Trends in Miniaturization and Efficiency

One of the driving forces behind the miniaturization of sensors is the advancement of MEMS. According to the latest data, it is predicted that the global MEMS market will reach beyond $18 billion by 2026, with a compound annnual growth rate (CAGR) estimated to be approximately 7.9%. These diminutive sensors are increasingly finding their way into consumer electronics, automotive systems, and medical devices, where limitations in space and energy efficiency are a matter of priority.

On the flip side, efficiency gains are provided by the production of ultra-low-power sensors. An example of this is the present-day IoT-enabled sensors that consume just a few milliwatts, hence greatly increasing the operation time of battery-powered systems. Consequently, such sensors can easily be deployed in remote and hard-to-reach places.

Further materials advances in the form of piezoelectric polymers and nanostructured semiconductor materials are ensuring better sensitivity and performance. These materials increase the sensors' detection accuracy and allow them to work under harsh environmental conditions. For example, pressure sensors are used in aerospace systems and wearables for high-precision real-time monitoring of biometrics.

The ever-increasing pace of development witnesses the interdisciplinary collaboration between materials science, engineering, and data analytics to break new grounds in sensor technologies.

Recently Posted

-

Understanding the Functions of Suction Valve and Discharge Valve in Pump Systems

December 18, 2025Industrial pump systems rely on precise mechanical coordination to transport fluids effectively. At the heart of this process are Read More

Read More -

Exploring Advanced Technologies in Air Compressor Discharge Valve Manufacturing

December 17, 2025The efficiency of any pneumatic system relies heavily on the performance of its smallest components. Among these, the air compress Read More

Read More -

Exploring Different Discharge Valve Types for Efficient Fluid Flow Management

December 16, 2025Industrial systems rely heavily on precision components to maintain safety, efficiency, and operational integrity. Among these com Read More

Read More -

How the Discharge Valve AC Affects Performance and Longevity of Cooling Systems

December 15, 2025The efficiency of any air conditioning system relies heavily on the precise coordination of its internal components. While the com Read More

Read More